2024 series Tooling

(HK1077)

Alcoa Fastening Systems

6

P

RINCIPLE

OF

O

PERATION

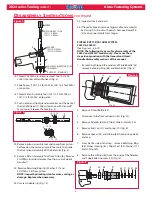

PULL PISTON

SPRING

DAMPER VALVE

EXHAUST

AIR PISTON

Hydraulic Oil

Air Pressure

Exhaust Air

HYDRAULIC

PISTON

THROTTLE VALVE

(PULL POSITION)

HYDRAULIC

PISTON

THROTTLE VALVE

(RETURN POSITION)

When the trigger is depressed the thro le valve moves to

down posi on, pressurized air is directed to the bo om of

the air piston, causing the piston to move upward (Fig.1a).

The air above the piston is exhausted and directed through

the center of the thro le valve and out the bo om of the

tool.

As the hydraulic rod moves upward, a column of

fl

uid is

forced into head, which moves the pull piston back. The

a ached nose assembly moves with the pull piston to start

fastener installa on.

When fastener installa on is completed, the trigger is

released. Air pressure with the assistance of a spring

causes the thro le valve to return to its up posi on.

Pressurized air is re-directed to the top of the air piston

(Fig.1b), causing the air piston and hydraulic rod to move

downward.

The air from below the piston is exhausted through the

bo om of the tool. Spring pressure returns the pull piston

to its home posi on. The damper valve impedes oil

fl

ow at

pinbreak helping prevent “Tool Kick”.

Fig. 1a

Fig. 1b

P

REPARATION

FOR

U

SE

The Model 2024 Installa on Tool is shipped with a plas c

plug in the air inlet connector. The connector has 1/4-18

female pipe threads to accept the air hose

fi

ng. Quick

disconnect

fi

ngs and 1/4” inside diameter air hose are

recommended. An air supply of 90 psi

(6.2 bar)

capable of

20 ³/s

(.57 m

³/s

)

must be available. Air supply should be

equipped with a

fi

lter-regulator-lubricator unit.

1. Remove plas c shipping plug from Air Inlet Connector

and put in a few drops of Automa c Transmission Fluid,

DEXRON III, or equivalent.

2. Screw quick disconnect

fi

ng into Air Inlet Connector.

3.

Set air pressure on regulator to 90-100 psi.

4. Connect air hose to tool.

5. Cycle tool a few mes by depressing and releasing

trigger.

6. Disconnect air hose from tool.

7. Remove Retaining Nut.

8. Select proper Nose Assembly for fastener to be

installed.

9. Screw Collet Assembly (including lock collar and shim if

applicable) onto Spindle. (Wrench Tight)

10. Slide Anvil over Collet Assembly and into counterbore.

11. Slide Retaining Nut over Anvil and screw Nut onto

Head.

12. Connect air hose to tool and install fastener(s) in test

plate of proper thickness with proper size holes. Inspect

fastener(s).

NOTES:

1. Air quick disconnect

fi

ngs and air hoses are not

available from Huck Interna onal, Inc.

2. On old style nose assemblies with lock collars,

Vibra-

TITE

should be used on collect threads, since there

is no staking hole provided on the 2024 pull piston.

Refer to nose assembly data sheets.

CAUTION: Do not use TEFLON tape on

threads. Use TEFLON in stick form only:

Huck P/N 503237