2024 series Tooling

(HK1077)

Alcoa Fastening Systems

10

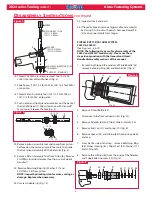

Head/handle 2024, 2024L

(Refer to Figures (7, 8 & 14)

NOTE:

Clean components with mineral spirits, or similar solvent;

inspect for wear/damage and replace as necessary.

Replace all seals of disassembled components. Use

O-rings, QUAD rings and Back-up rings in

Service Parts

Kit, P/N 2024KIT or 2024VKIT

Smear LUBRIPLATE

130AA or PARKER-O-LUBE on O-rings, QUAD rings,

Back-up rings and mating parts to ease assembly.

Assemble tool taking care not to damage O-rings, QUAD

rings, or Back-up rings.

1. If removed, position Cable Assembly (2) in Trigger

(5) slot and slide Dowel Pin (3) through holes in

trigger and cable assembly. Position assembled

trigger in handle and drive Pin (4) through holes in

handle and trigger (Fig. 14).

2. Screw Nose Adapter (8) into Head (1) and tighten.

3. Thread POLYSEAL Insertion/removal Tool (121694-

2024) into head.

4. Assemble piston (6), Polyseal (18) and retaining ring

(16) (Fig 7).

Note Polyseal orientation.

5. Assemble front gland (15), O-ring (12), Back-up

ring (11), Polyseal (14) and Gland Cap (10).

Note

Polyseal orientation.

6. Thread Piston Assembly Tool (123111-2 for 2024,

& 2024V) or (123111-4 for 2024L, & 2024LV) onto

Piston (6). Slide complete Gland Assembly and

Wiper Seal (9) onto Piston (6).

7. Install assembled components in gently from rear of

tool using a press as shown in (Fig. 8).

8. Remove Piston Assembly Tool (123111-2 or 123111-

4) and POLYSEAL Insertion / removal (121694-

2024) Tool.

9. Install Rear Wiper Seal (23) into End Cap (21) (Fig.

14).

10. Slide Spacer (22) and Spring (19) into End Cap

(21) and then thread End Cap assembly into rear

of Head.

NOTE: For 2024V please reference

Assembly of Pintail Bottle and Vacuum System

procedure.

(Refer to Figures 5, 6 & 10)

General:

(Refer to Figures 2 & 9)

11. Hold Head/Handle (1) inverted in vice (with soft

jaws). Place inverted Cylinder Assembly (35) on

base of handle. Timing pin maintains orientation.

12. Assemble Gland assembly (25) with new seals

(Fig. 9). Note orientation of polyseal. Apply Anti-

Seize Compound (Huck P/N 508183) to threads of

Gland Assembly. Screw gland into head/handle and

Torque to 50 ft. lbs. using 1 3/8 socket wrench.

13. Push Bumper (34) fi rmly over gland.

NOTE: The

side of the bumper with two slots must face

toward the bottom of the tool.

A

SSEMBLY

I

NSTRUCTIONS

2024

ALL

MODELS

LIP, THIS DIRECTION

16 17 18

6

PISTON ASSEMBLY (BULLET)

123111-2 (for 2024 & 2024V) OR

123111-4 (for 2024L & 2024LV)

11 12 15

14

10

9

LIP, THIS DIRECTION

FIG. 7

1

8

PRESS

POLYSEAL INSERTION TOOL

121694-2024

SUPPORT

FIG. 8