Page 8

Nozzle Installation

The nozzle should be threaded onto the outlet of the monitor. Place the pattern actuator in a position that does not

stretch the power cord, and then tighten the swivel.

Verify that the actuator orientation does not interfere with

the monitor.

Controller Box Installation

This monitor is used with a 6032 Universal II Controller. It normally mounts on or below the deck and must be mounted

close enough to the monitor so that the 10 foot cable of the monitor wiring harness has sufficient slack to allow the

monitor to travel through its full rotational range. Refer to the “6032 Universal II Controller Installation, Operation &

Maintenance Manual” (part number 122552) as a guide.

Do not extend the monitor wiring harness.

Electrical Installation Instructions

Make the I/O and power connections to the 6032 controller and then plug the monitor harness into the controller. Refer

to the “6032 Universal II Controller Installation, Operation & Maintenance Manual” (part number 122552) as a guide

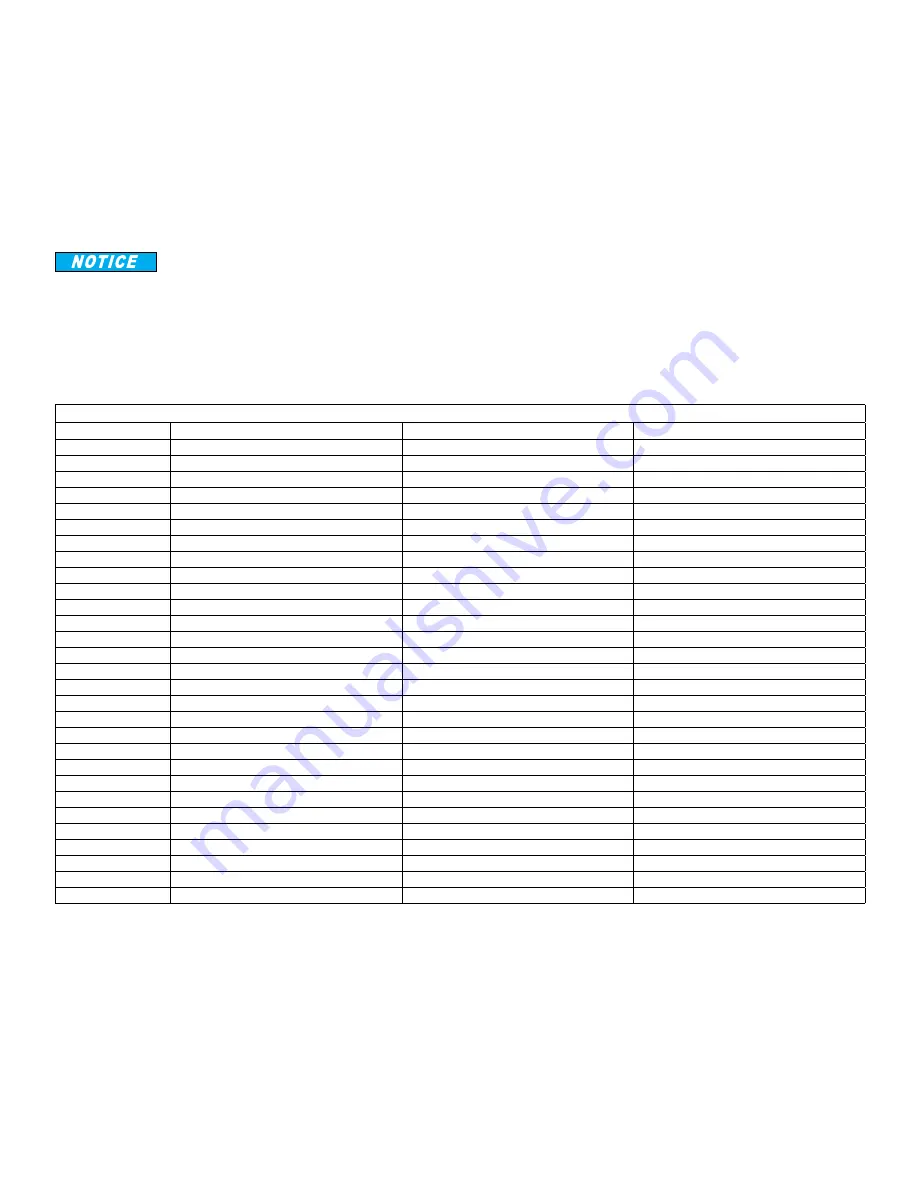

Harness 721582 for Power & Signal Connector J1 on Controller

Contact Position

Function

Comments

Wire Color & Size

1

Power In – Vehicle Battery (+12/24 VDC)

Red – 12 AWG

2

Power In – Vehicle Battery (−)

Black – 12 AWG

3

Power In – Auxiliary Battery (+12/24 VDC)

(Optional)

Green – 12 AWG

4

Power In – Auxiliary Battery (−)

(Optional)

Black – 12 AWG

5

Output – H-Bridge #5A

Red – 16 AWG

6

Output – H-Bridge #5B

Black – 16 AWG

7

Output – Logic #1

Panel LED

Brown – 16 AWG

8

Output – Logic #2

Discharge

Red – 16 AWG

9

Output – Logic #3

Orange – 16 AWG

10

Output – Bi-stable Relay Common

Yellow – 16 AWG

11

Output – Bi-stable Relay N.O.

Green – 16 AWG

12

Output – Bi-stable Relay N.C.

Blue – 16 AWG

13

Input – Switch #1 (System Enable)

Brown – 18 AWG

14

Input – Switch #2

+ Right / Left -

Red – 18 AWG

15

Input – Switch #3

+ Up / Down -

Orange – 18 AWG

16

Input – Switch #4

+ Stream / Fog -

Yellow – 18 AWG

17

Input – Switch #5

+ Valve Open / Close -

Green – 18 AWG

18

Input – Switch #6

+ Gallonage High / Gallonage Low -

Blue – 18 AWG

19

Input – Switch #7

+ Oscillate Set / Pause -

Violet – 18 AWG

20

Input – Switch #8

+ Deploy / Stow -

Gray – 18 AWG

21

Input – Switch #9

+ Aux Agent 2 / Aux Agent 1 -

White – 18 AWG

22

Power Out – Peripheral (+12/24 VDC)

Powers the System Enable (#13)

Brown – 18 AWG

23

Data – J1939 CAN High (+)

Yellow – 18 AWG

24

Data – J1939 CAN Low (−)

Green – 18 AWG

25

Power Out – Peripheral (−)

Drain – 18 AWG

26

Data – Proprietary CAN High (+) (Unused)

Sealing Plug

27

Data – Proprietary CAN Low (−) (Unused)

Sealing Plug

28

Data – V-Mux Com A (+) (Unused)

Sealing Plug

29

Data – V-Mux Com B (−) (Unused)

Sealing Plug

Table 1 – Power & Signal Harness Connections