5. Periodic Inspection/Maintenance

5

-

8

5.6.5 Change Compressor Oil

[At 300 hours for the first change and at every 500 hours thereafter]

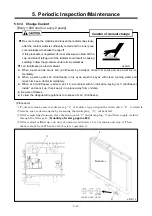

Refilling of compressor oil

When you refill the separator receiver tank with compressor oil,

stop the engine, and make sure that the pressure gauge indi-

cates 0MPa and there is no residual pressure in it, and then

gradually loosen the oil filler cap for refilling oil.

Note residual pressure in the receiver tank could force both ex-

tremely hot compressed air and oil to jet out and you may be

scalded or seriously injured.

Even continuous oil replenishment cannot improve its deterio-

rated condition. Be sure to change the oil completely at every

scheduled interval.

Do not mix it with other brand oil, or it will cause poor perform-

ance and shorten the life of the compressor oil. (But fresh com-

pressor oil could accept a mixture of small amount of different

brands.)

Running the unit with old and deteriorated compressor oil will

cause damage to bearings, or serious accident like ignition in a

separator receiver tank. Be sure to change the oil completely at

every scheduled interval.

Follow the designated regulations to dispose of compressor oil.

W010

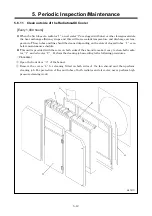

(Procedures)

①

Remove the oil filler cap

“

2

”

of separator receiver tank

“

1

”

.

②

Open drain valve

“

3

”

to discharge waste oil from the tank.

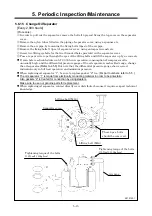

③

In case of replacement, completely discharge all the oil left

in the compressor body, separator receiver tank

“

1

”

, pipes

and oil cooler. If wasted oil is left in the unit, this residual

oil will greatly shorten the life of the newly replenished oil.

④

Be sure to close drain valve

“

3

”

after the wasted oil is

completely discharged.

⑤

Fill the designated quantity of new oil into the oil filler port.

[Quantity of oil

:

approx.105[Quantity of oil

:

approx.105

L

]

(For recommendation oil, refer to 4 .3)

⑥

After oiling, tighten the cap

“

2

”

in its place while paying

attention not to let dust get in the tank.

⑦

Start the engine for a short while, then replenish the oil to

fill shortage. Repeat this procedure for 2 to 3 times to check

if the oil level has reached its appropriate point. Be careful

not to overfill the oil.

A070199

1

2

3

CLOSE OPEN FULLY

OPEN

Содержание PDSE900S-4B1

Страница 1: ......

Страница 14: ...1 Safety 1 11 The pasting position of safe warning label is as follows 5 4 3 6 6 8 7 11 A070196E 9 1 2 10 2 6...

Страница 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Страница 61: ...9 Wiring Diagram 9 1 A090360E...

Страница 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Страница 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Страница 67: ......