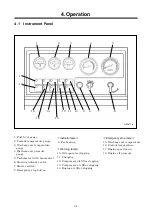

4.Operation

4

-

6

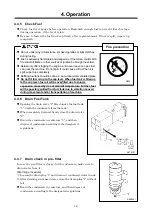

4.4 Check before Starting Unit

Be sure to check the unit before operation.

When any abnormality is found, be sure to repair it before restarting the unit.

Be sure to make daily checks before operation. If the unit is operated without prior check and without no-

ticing its abnormality, such operation could cause seizure of components or may even cause fire.

4.4.1 Check Engine Oil Level

Unit should be on level before checking oil level.

When you check oil level after you have once started

operation, wait 10 to 20 minutes after stopping engine,

before checking the oil level.

(Procedure)

①

Pull out the oil level gauge

“

1

”

, and wipe it with a

clean cloth.

②

Then, re-insert the oil level gauge

“

1

”

fully and

pull it out again. If the oil level gauge shows the oil

level between LOW and HIGH, it is normal.

③

When the oil level is below its LOW, add engine oil

from oil filler port

“

2

”

.

While checking oil level, check also for contamination.

If the oil is found dirty, contaminated or should it be

changed according to the periodic inspection list,

change the oil.

(See 5.6.1)

Never fill oil more than HIGH level.

Oil level gauge

HIGH

LOW

When oil level is

within this zone,

it is normal.

A070134

1

2

Check before starting unit

Содержание PDSE900S-4B1

Страница 1: ......

Страница 14: ...1 Safety 1 11 The pasting position of safe warning label is as follows 5 4 3 6 6 8 7 11 A070196E 9 1 2 10 2 6...

Страница 60: ...8 Specifications 8 2 8 2 Outline drawing A040390 1 A070197...

Страница 61: ...9 Wiring Diagram 9 1 A090360E...

Страница 62: ...10 Piping Diagram 10 1 10 1 Compression air Compressor oil PDSE900S PDSF830S 4B1 A070141E 2...

Страница 63: ...10 Piping Diagram 10 2 PDSG750S 4B1 A070220E 2...

Страница 67: ......