M

ain

te

nanc

e

Chillers

TurboChill™ R1234ze Air Cooled and FreeCool

146

Chiller Technical Manual 7752785 V1.12.0_10_2018

Operational Maintenance Checks

Owners Responsibility

To ensure that the chiller can be maintained correctly ensure the following requirements are met.

Maintain a safe working environment around the chiller, free from obstructions and debris.

The unit shall follow the maintenance schedule below as a minimum.

The equipment contains live electrical and moving parts, ISOLATE prior to maintenance or repair work.

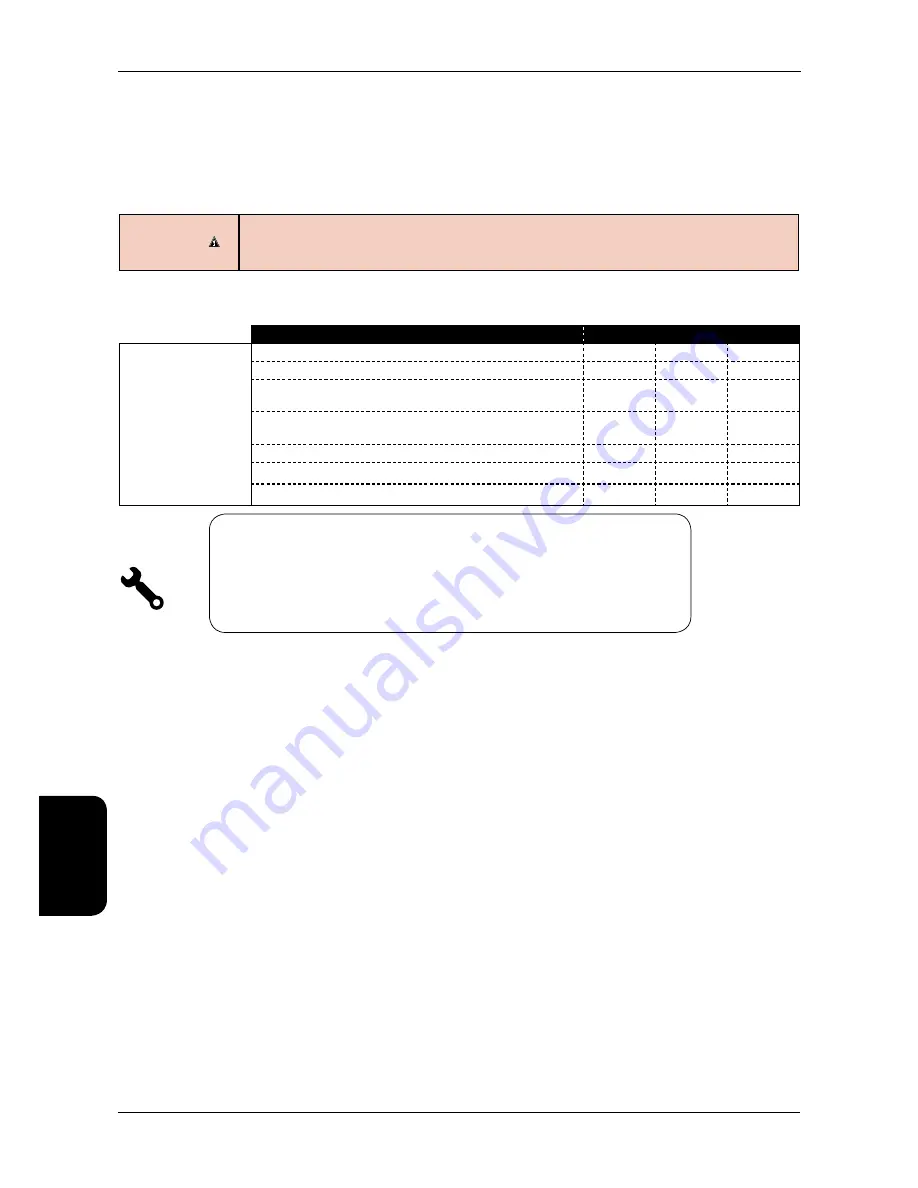

Maintenance

General Inspections

Procedures

Task

Frequency

General Inspections

3 Mths

12 Mths

60 Mths

Check for visible mechanical damage to unit.

●

Visually inspect the unit for general

wear and tear, treat metalwork.

●

Rust should be inhibited, primed and

touched up with matching paint.

Check for excess vibration from other rotating equipment.

●

Clean Microchannel condenser coil

●

Ensure no debris has collected under compressor housing

●

Service Tools/Test Equipment

•

Touch-up Paint

•

Stiff Brush

Safety Equipment

•

Safety Glasses/Goggles

Coil Cleaning

To clean micro channel condenser coils use detergent and a stiff bristled brush.

For heavy dirt, use either a high pressure water with a broad spray pattern or a non acidic cleaner (Ph ≥7 <10.5).

Do not steam clean.

Debris under compressor housing

Debris under the compressor housing can cause the refrigeration ventilation fan to underperform.

Ensure lock off procedures are carried out accordingly.

If inverter driven pumps are used ensured at least 5 minutes is allowed for them to discharge any

electrical charge.

CAUTION

Содержание TurboChill TCC11R04G-01

Страница 1: ...Technical Manual TurboChill 200kW to 1360kW Air Cooled TCC and FreeCool TCF Chiller R1234ze E ...

Страница 195: ...195 Chiller Technical Manual 7752785 V1 12 0_10_2018 Chillers TurboChill R1234ze Air Cooled and FreeCool ...

Страница 196: ...196 Chiller Technical Manual 7752785 V1 12 0_10_2018 Chillers TurboChill R1234ze Air Cooled and FreeCool ...