MN-745

6

GETTING STARTED

1. Raise the vehicle up with a hoist or jack up the rear with a jack. Place Jack stands under

the axle and lower the vehicle down if using a frame contact hoist (so vehicle is at curb

height).

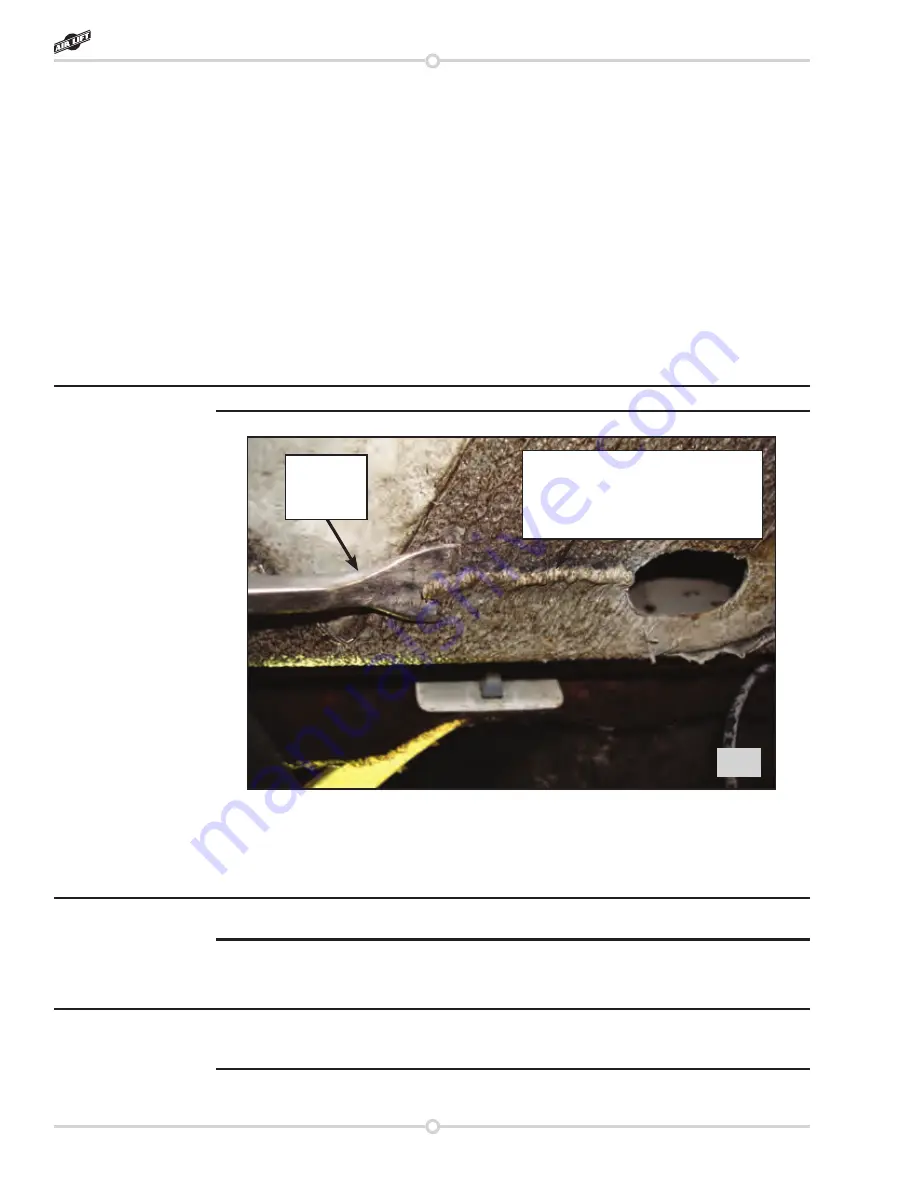

2. The air spring assembly fits forward of the axle. On some models there is a thick coat

of a body filler type substance that will need to be removed where the upper bracket

contacts the frame (fig. 6). Set the left and right hand assembly in place on the axle,

make sure the “finger” of the lower bracket is over the leaf spring U-bolt. Align the spring

so it is perpendicular to both upper and lower brackets. Mark the frame in the area that

the upper bracket makes contact with the frame and remove both assemblies. This is

the area that you will need to remove the “body filler” material so that the bracket fits flat

to the frame. Use a gasket scraper or a chisel to remove the material.

I use an air chisel with light pressure to remove the material.

3. Set the assemblies back in place forward of the axle with the holes in the upper bracket

pointing inboard.

4. With the finger of the lower bracket over the stock U-bolt, attach it to the leaf spring with

the U-bolt (H), clamp bar (G), flat washers (K) and nyloc nuts (J) (fig. 7).

Offset the lower bracket to the inside of the vehicle on the leaf spring before tightening

hardware. Torque to 16ftlbs and repeat for the opposite side.

5. With the lower bracket attached to the leaf spring, align the upper bracket on the frame

so that the air spring is perpendicular to both the upper and lower bracket (fig. 8). Keep

the bracket centered on the frame, between the outside and inside while positioning.

It may be helpful to have slight pressure in the air spring for aligning and attaching the upper

bracket to the frame. Cut the air line (L) in two equal lengths (see hose attaching instructions)

and insert the air line into the air spring fittings. Inflate the springs to 5psi (or less).

6. Using the upper bracket as a template, drill two ¼” holes through the bottom of the frame

(fig. 8).

Installing the RideControl System

fig. 6

Bead of “body filler” type substance

that will need to be removed so

that the upper bracket will fit flush

to the frame

Scrapper

removing

bead

NOTE

NOTE

NOTE

RideControl