Version October 2015

EN

17

agru EF 110-B User’s Manual

If an inside beadless welding operation with balloon is at hand, manual

data input must also include the pressure inside the balloon (P1) and

the cooling time after the welding process (Tc). This cooling time has

to be observed. If it were cancelled or aborted, the welding system will

reference the joint as a faulty welding operation.

4.5.2 Entering the String of Numbers

If this option was chosen in the manual parameter input menu, the “Enter

Fitting Code” display shows. The 24 or 34 characters of the electrofu-

sion fitting code to be entered display as plus characters ( + ). Use the

alphanumeric keypad (see last Info in Sect. 4.1) to enter the code and

press START/SET to confirm your input and have it decoded. If the code

entered is not correct, a “Code Error” message appears; check the string

of numbers and correct as needed. If the code is correct, the decoded

data is displayed, and the “Start ?” message (see Display 10) indicates

that the unit is ready to start welding.

Inside beadless welding with inside balloon is possible only when a

34-character code is entered, since a 24-character code does not in-

clude any data on controlling balloon pressure and cooling time. If a

24-character code is entered, the system starts a welding process with

balloon control.

Important

Only when the manual welding parameter input includes either

a balloon pressure (P1) of more than 0 bar or a 34-character

fitting code, inside beadless welding with balloon control is

possible. If it does not, the balloon control subsystem is not

even started when the welding process begins.

Info

If a cooling time (Tc) is entered in the manual parameters, this

cooling time has to be waited before the cable between the

system and the electrofusion fitting is disconnected. If a cool-

ing time was entered and yet the cooling stage was cancelled,

the system will assess the joint as being faulty.

4.6 Performing the Welding Process

4.6.1 Facing the Component Ends before Welding

If the diameter of the components to be jointed is smaller than the maxi-

mum size of the clamps, install the appropriate reducers in the clamps.

This does not require any tools. Magnets hold the reducer inserts

in the clamps.

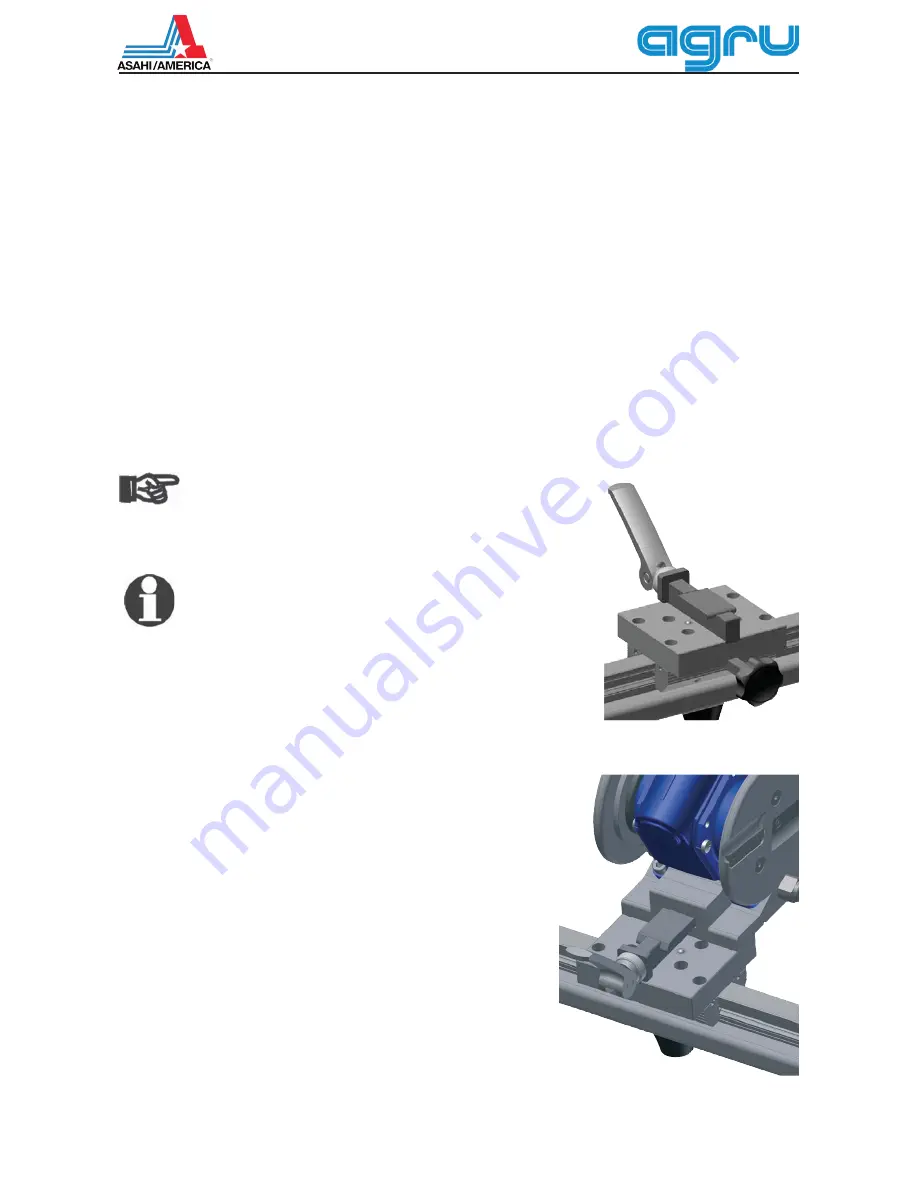

Unlock all three carriages (left-hand and right-hand clamp and

facing tool/fitting clamp carriage) at their respective star knobs.

Then slide the power facing tool as far as it will go onto the seat

on top of the carriage of the mechanical structure and lock it in

place by pushing the quick release lever down.

Insert the components to be jointed into the clamps, one of them

left, the other, right of the facing tool. Be sure that on both sides

they project enough over the clamps on the inside for the blade

of the facing tool to be able to cut a sufficient length of material

while facing. The spacer pins on both sides of the facing tool will

facilitate this process: when the component butts touch the the

facing tool, the spacer pins must not touch yet the inside surface

of the clamps.

Reposition the outer clamps on both sides as needed by loosening

then retightening the thumb screw at their far end.

Star knob locking the fitting

clamp/facing tool carriage

(identical knob on the other carriages)

Sliding the facing tool onto the seat on

top of its carriage; to lock, lower quick

release lever on the front of the seat