Version October 2015

EN

11

agru EF 110-B User’s Manual

The welding process in monitored in its entirety and saved to a welding

report. All welding reports can then be downloaded to a USB stick as

an abstract or extended report in the PDF format or in the DataWork

database management format.

Using the menus, the machine can be customized to the application at

hand (see Sect. 4.3, Configuring the Machine).

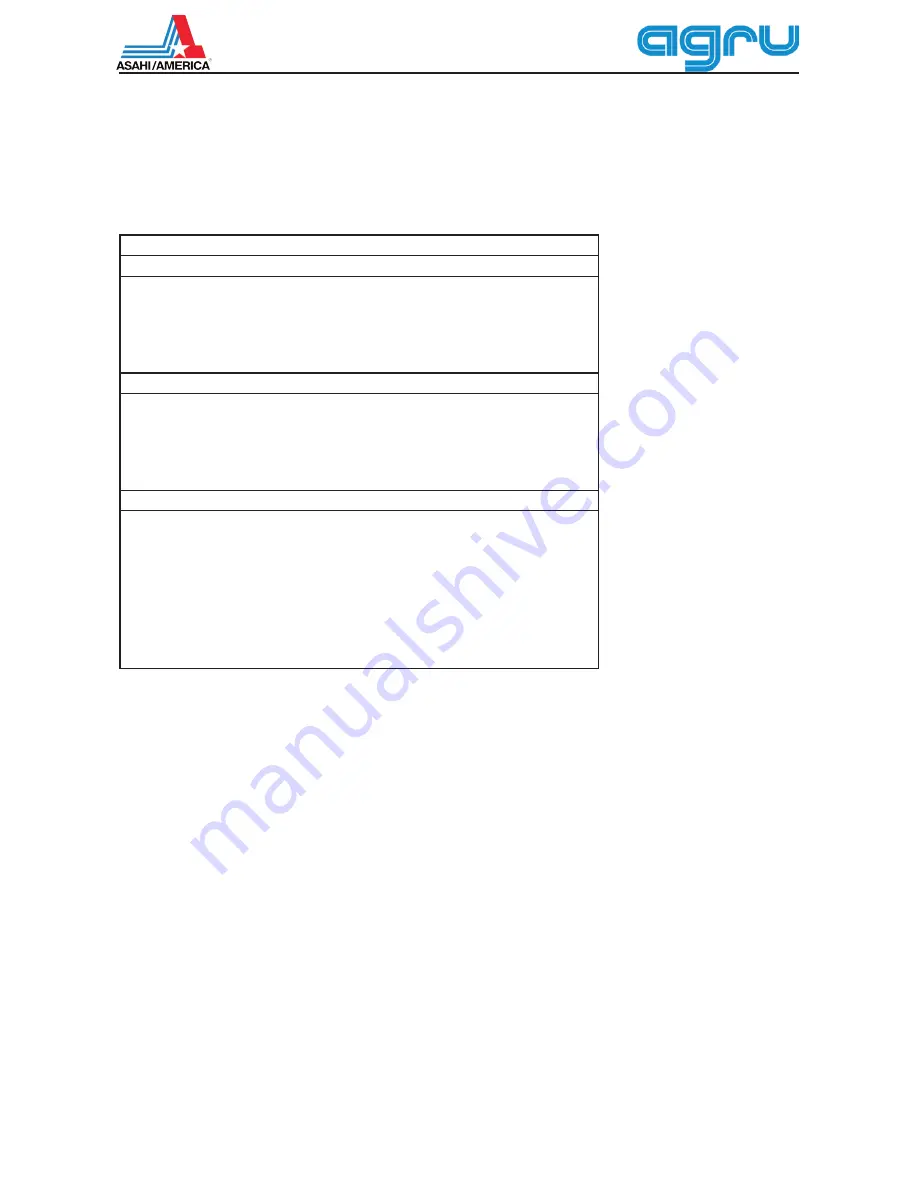

3.2.4 Specifications

agru EF 110-B

Power Supply Characteristics

Voltage

Frequency

Rated Power

Input Current

Max. Output Current

Output Voltag

230 V AC

50 / 60 Hz

2000 VA, 80% duty cy.

approx. 10 A

approx. 40 A

8 V - 48 V

Welding Operation Specs

Ambient Temperature (operation)

Ambient Temperature (storage)

Operating Range

Ingress Protection

Welding Report Memory Capacity

USB Communication Interface

– 10°C to + 45°C (+ 14°F to 113°F)

– 25°C to + 65°C (– 13°F to 149°F)

max. component size 110 mm

IP 54

10,000 reports

USB v 2.0 (480 mbit/s)

Dimensions and Weight

Dimensions (W x D x H)

Mechanical Structure

Control Unit

Transport Box

Weight

Mechanical Structure

Control Unit

Facing Tool

Transport Box with All Elements

Empty Transport Box

675 x 200 x 190 mm

420 x 320 x 240 mm

800 x 600 x 608 mm

approx. 6 kg

approx. 15 kg

approx. 4 kg

approx. 83 kg

approx. 42 kg

3.3 Welding Process Overview

The welding system allows welding electrofusion fittings that feature a

bar code. Every e-fitting is provided with a tag with one or two bar codes

on it. The structure of this code is internationally standardized. The first

code, encoding the data on proper welding, complies with ISO 13950,

the second code, if present, encoding the component traceability data,

complies with ISO 12176. The welding parameters can also be entered

manually.

When using an inside balloon in the pipe, beadless welding is possible.

To automate a beadless welding process, a special code with 34 digits,

which builds on the abovementioned 24-digit code^s, has to be read from

a RFID transponder card or entered manually. The parameters related

to balloon pressure can also be entered manually.

The welding system is microprocessor-controlled and:-

•

controls and monitors the welding process in a fully automated way,

when the welder starts it after component preparation,

•

determines welding duration depending on ambient temperature,

•

shows all information on the display in plain text.

The welding process is performed as follows:

•

All welding parameters and traceability data for the components

are read from a RFID transponder card or a bar code or entered