Version October 2015

EN

15

agru EF 110-B User’s Manual

the report. To say that the joint number is related to the job, or commis-

sion, number means that the system checks, when a commission number

was entered, whether it exists already in the internal memory. If so, it

takes the highest existing joint number for that commission, increments

it by 1, and applies this new joint number to the next welding operation

in that commission.

4.4 Configuring the Welding System

In Display 3, the welder has the possibility to:

•

read the welding parameters from a bar code or a RFID card and

start a welding process (move on to Section 4.6);

•

enter the welding parameters for the next welding manually and

start the welding process (move on to Section 4.5);

•

change the sytems settings in the configuration menu (press the

MENU key).

Accessing the menu requires an access code (see Display 6). The menu

is structured according to three submenus, the third of which, “Sensor

Parameters,” does not contain any parameters important for welding, but

only for set-up and maintenance work. They are therefore protected by a

second access code that is disclosed only to authorized personnel. The

configuration menu has the items listed in the following table.

To toggle from « On » to « Off » or vice versa for an option, press the

Ö

cursor key, to open a submenu or go to an additional screen for an

option, which is indicated by the letter – M –, press the MENU key.

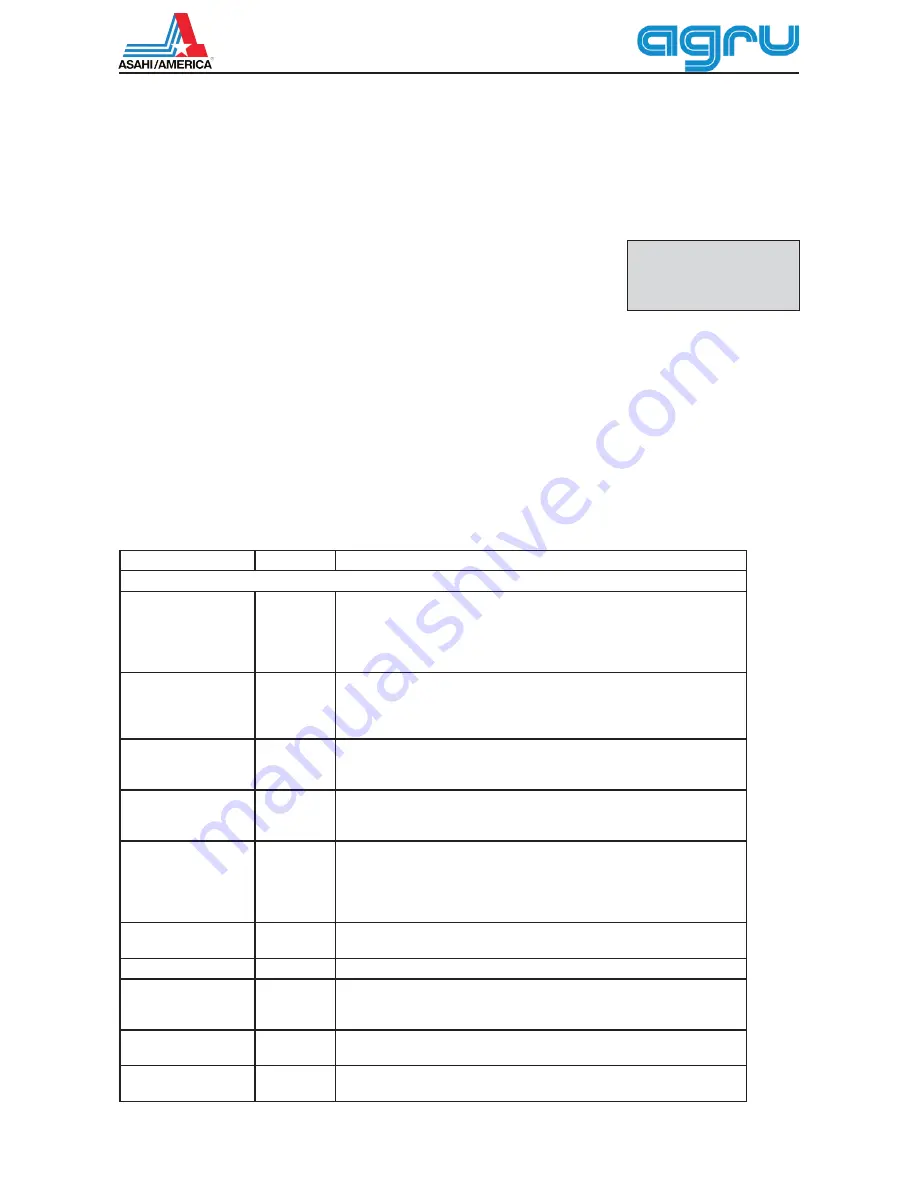

Designation

Setting

Description / Data to be entered

—— “Settings” submenu ————————

AutoWeld

ON / OFF

"on” means that for two subsequent welding with identical welding/

fitting parameters, the parameters of the preceding one are applied

automatically to the following one (see Sect. 4.6.4), “off,” that the

parameters have to be read or entered again for every new wleding

operation.

Check Code Expiry

ON / OFF

"on” means that the welder identification code has to be current and

not expired (default period of validity 2 years from code issuance),

or the welding operation cannot be started, “off,” that the validity of

the code is not checked at all.

Memory Control

ON / OFF

if ON: Machine stops when the memory is full;

if OFF: Machine overwrites the oldest report when the memory is

full.

Manual Input

On / Off

"on” means that the manual input of welding parameters or

computed parameters is possible, “off,” that the manual input is not

allowed.

Welder Code Options

Menu

In a sub-menu, it can be determined when the welder code, if it is

enabled at “Recording,” has to be entered: always, i. e. before evey

single welding operation, only before the first welding operation after

switching the unit on or only after the first welding operation of a

new day/date..

Language

Menu

In a sub-menu, the language in which display texts and reports are

edited can be selected.

Date/Time

Menu

In a sub-menu, date and time can be set.

Buzzer Volume

Menu

In a sub-menu, the volume of the audible signal that the machine

emits to validate the execution of a given step in the process can be

set.

Temperature Unit

(°C / °F)

Menu

In a sub-menu, the temperature unit used for displaying and saving

welding data can be selected.

Unit of Pressure

(bar / psi)

Menu

In a sub-menu, the unit of pressure used for displaying and saving

welding data can be selected.

Display 6

Enter Menu Code

******