46

22.05 – 4037365_03

15 SYSTEM WATER CONTENT

MINIMUM SYSTEM WATER CONTENT

For correct unit operation, there must be a suitable amount of water in the system. A sufficient quantity of water not only ensures machine stability, but also helps avoid a high

number of hourly compressor start-ups.

To calculate it, use the formula: Unit rated cooling capacity (ton) x table value (gal/ton) = Minimum system content (gal).

Size

0280

0300

0330

0350

0550

0600

0650

0675

0750

0800

0900

1000

1100

1250

Minimum system water content

Minimum water content for air conditioning

A

gal/ton

3.7

Minimum water content for processes

A

gal/ton

7.4

Note

: the water content referred to in the tables corresponds to the amount of water effectively useful for inertial purposes; this value does not necessarily coincide with the

entire system water content, and must be calculated on the basis of the system layout and operating modes.

A example is given below, but it does not cover a possible situation.

Example

: for a chiller/heat pump equipped with a primary and a secondary circuit, and in which the zone pumps of the secondary circuit could (even occasionally) be turned

off, only the water content of the primary circuit has value of useful water content for the counting purposes.

If you are in any doubt, please refer to the relevant technical documentation or contact the AERMEC Technical-Commercial Service.

ATTENTION It is recommended to design systems with high water content (minimum recommended values shown in tab), in order to limit:

—

Number of peaks made by the compressors

—

The reduction of water temperature during defrosting cycles in the winter period for heat pumps.

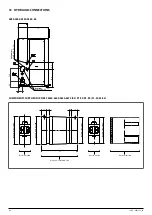

MAXIMUM SYSTEM WATER CONTENT

Units with the hydronic kit mounted come standard with the expansion vessel set at 21.8 psi and the pressure relief valve.

The maximum system water content depends on the capacity of the expansion vessel and on the calibration of the pressure relief valve.

Size

0280

0300

0330

0350

0550

0600

0650

0675

0750

0800

0900

1000

1100

1250

INTEGRATED HYDRONIC KIT: 00

Hydronic kit

Expansion vessel number

A

no.

/

Expansion vessel capacity

A

gal

/

/

/

/

/

/

/

/

/

/

/

/

/

/

Storage tank number

A

no.

/

Storage tank capacity

A

gal

/

/

/

/

/

/

/

/

/

/

/

/

/

/

Pressure relief valve

A

n°/psi

/

INTEGRATED HYDRONIC KIT: 01, 02, 03, 04

Hydronic kit

Expansion vessel number

A

no.

1

Expansion vessel capacity

A

gal

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

Storage tank number

A

no.

1

Storage tank capacity

A

gal

79.3

79.3

79.3

79.3

132.1

132.1

132.1

132.1

132.1

132.1

132.1

132.1

132.1

132.1

Pressure relief valve

A

n°/psi

1/87.0

INTEGRATED HYDRONIC KIT: P1, P2, P3, P4

Hydronic kit

Expansion vessel number

A

no.

1

Expansion vessel capacity

A

gal

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

Storage tank number

A

no.

/

Storage tank capacity

A

gal

/

/

/

/

/

/

/

/

/

/

/

/

/

/

Pressure relief valve

A

n°/psi

1/87.0

The table gives an example of the maximum water content calculated at the indicated operating conditions and only to protect the unit.

If the volume of water in the system is higher, add another expansion vessel of the correct size.

System water temperature max/min

°F

104/39.2

Hydraulic height

Ft

98.4

82.0

65.6

49.2

≤40.19

Expansion vessel pre-load

psi

46.4

40.6

33.4

26.1

21.8

Water content maximum

gal

574.3

699.0

823.7

948.4

1,017.6

System water temperature max/min

°F

140/39.2

Expansion vessel pre-load

psi

46.4

40.6

33.4

26.1

21.8

Water content maximum

gal

258.4

314.4

370.9

426.9

457.5

The data in the table refer to units with a 6.3 gal. expansion vessel.