28

22.05 – 4037365_03

— Handle the unit with care and without sudden movements;

— Do not stand under the unit during lifting;

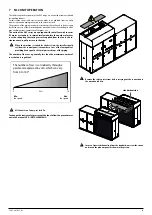

HANDLING WITH A FORKLIFT

The forks of the forklift must pass completely below the load. During descent, the

load must be lowered in reverse, with the pillar inclined to the rear, during ascent

the load must be lifted in forward gear, with the pillar inclined to the rear.

Handling with a forklift for sizes from 0280 to 0675

STORAGE

It is possible that the units may not be immediately installed upon receipt. If they

are stored for a medium-long period of time, the following procedures are recom-

mended:

— The units cannot be stacked;

— Check for any damage

— Make sure there is no water inside the hydraulic systems;

— Do not remove the protections from the heat exchanger;

— Do not remove the plastic protective films;

— Make sure that the electrical panels are closed;

— Before using the equipment, put all the supplied items in a dry and clean loca-

tion so that they can be used in the future.

The minimum and maximum unit storage temperature depends on the

type of refrigerant used, see the table. Above this limit, there is a risk of

refrigerant leaks through the pressure relief valves.

Maximum storage temperature

Refrigerant

Type

Class

Min temp. (°F)

Max. temp. (°F)

R134a

HFC

A1

-4.0 °F

< 122.0 °F

R410A

HFC

A1

-4.0 °F

< 122.0 °F

R513A

HFC

A1

-4.0 °F

< 122.0 °F

R32

HFC

A2L

-4.0 °F

< 122.0 °F

R1234ze

HFO

A2L

-4.0 °F

< 122.0 °F

PLACE OF INSTALLATION

All units in this series are designed for indoor installation in machin-

ery rooms only, according to EN378. Attention:

the ambient tempera-

ture inside the technical room where the unit is installed must not exceed

113.0 °F, otherwise ventilation systems must be installed.

The location of the unit must be defined by the system designer or a person who is

an expert in the material and must consider both the purely technical requirements

as well as any local laws in force.

For unit installation it is important to perform the following preliminary prepara-

tion tasks:

The following must be avoided

— Locations with aggressive atmospheres;

— Areas in which the unit's noise level could be amplified due to reverberations

or resonance;

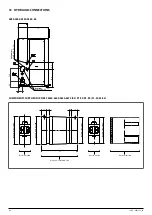

POSITIONING

The units must:

— They must be installed in an area that cannot be accessed by the public and/or

be protected against access by unauthorised persons, if necessary also install

fences;

— Be positioned on a levelled surface that is able to support the weight of the

unit with the refrigerant load and complete water, in addition to the occasional

presence of maintenance equipment;

— Creating a support base that is independent from the main building is always

advisable to avoid the transmission of vibrations;

— It is recommended to place a rubber sheet between the floor and the equip-

ment or use suitably sized anti-vibration supports.

— The unit must be fixed to the anti-vibration supports and these firmly fixed

to the concrete base, see chapter weight distribution and minimum technical

spaces;

— Check that the contact surfaces of the anti-vibration supports are levelled at the

base. If necessary, use spacers or level the base, but in any case make sure that

the anti-vibration supports are placed flat on the surfaces of the base;

— The use of anti-vibration supports MUST be done in combination with the in-

stallation of flexible couplings in the unit's water pipes. The anti-vibration sup-

ports must be fixed to the unit BEFORE being earthed. AERMEC is not responsi-

ble for selecting the capacity of the anti-vibration supports;

— Each side of the unit must have space to allow all routine and extraordinary

maintenance to be performed.

— During installation, check that atmospheric or environmental agents do not af-

fect or corrode the components of the cooling circuit, causing refrigerant leaks

into the environment. Where present, proceed with the appropriate measures

in compliance with the regulations in force.