22.05 – 4037365_03

29

7

NLC UNIT OPERATION

The chillers and the heat pumps of the NLC range are air-cooled machines suitable

for installing indoors.

For this reason the air that crosses the coil needs to be expelled from the utility

room using suitable piping connected to the machine itself.

The presence of the piping involves pressure drops that will need to be overcome

by the fan; the size of these losses depends on various factors like the length of the

pipe, the dimensions, complexity of the pipes, etc.

The units of the NLC series are equipped with radial fans with inverter

EC motor as standard, to immediately modulate the number of motor

revs, thus adapting the static pressure supplied from the fan to the in-

stantaneous drop of pressure in the tube.

When the machine is started for the first time, the installer should

set (from the control panel) the number of revs of the fan capable of

providing head equal to the total pressure drops of the piping.

The number of fan revs is generally less than the maximum number of

revs the fan is capable of.

0

10

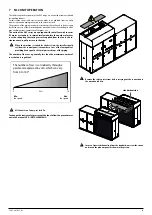

The number of revs is set indirectly through a

parameter expressed in volts, which can vary

from 0 to 10V:

Min.

fan speed

Max.

fan speed

Volt

All the units are factory-set for 0 Pa.

To change the static useful pressure of the fans, follow the procedure set

out in the manual USE - INSTALLER MENU

Remove the safety protections before carrying out the connection to

the air exhaust ducts.

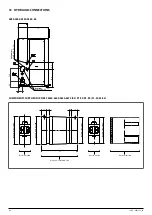

standard version

In case of inverted channeling from the standard, unscrew the screws

and invert the plenum panel as shown in the picture.