ENGINE

4-27

◎

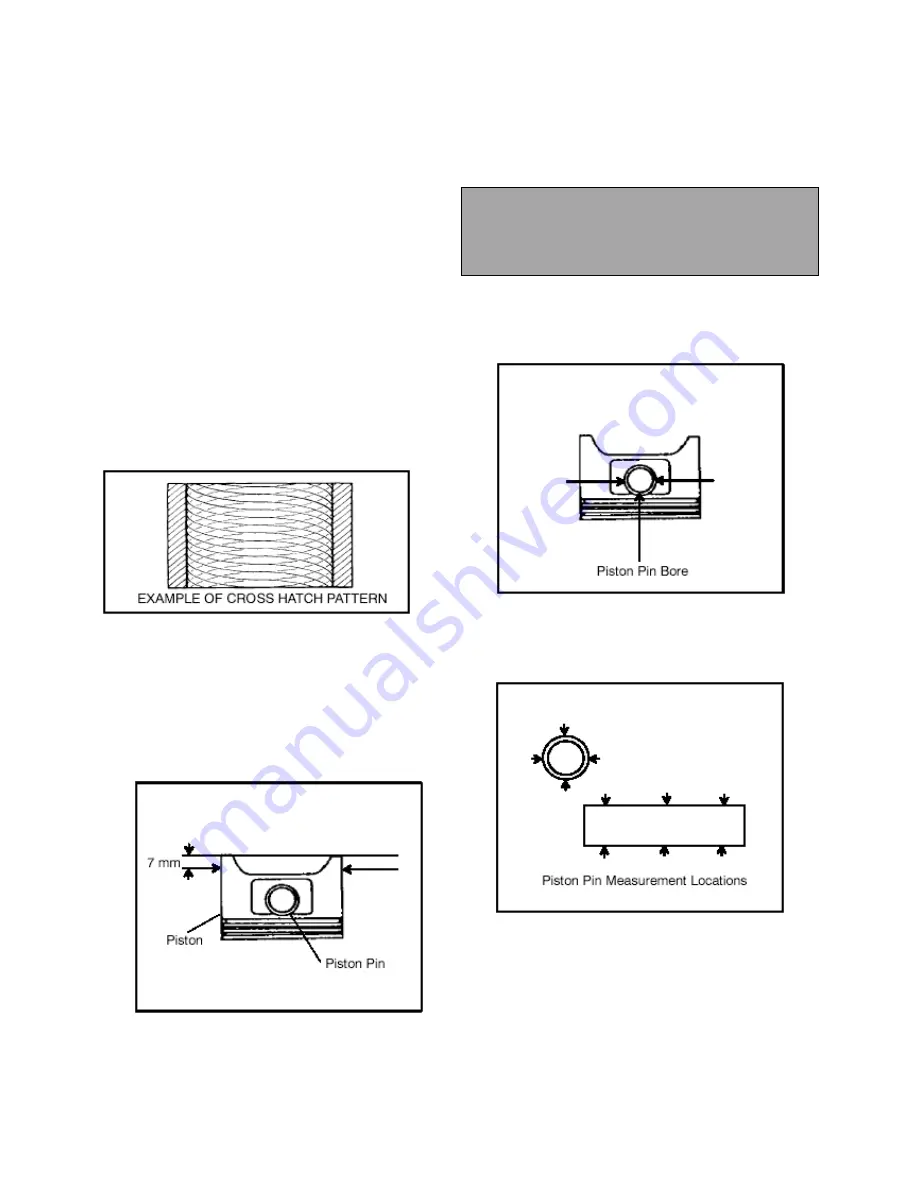

After honing has been completed, inspect cylinder for

thinning or peeling.

IMPORTANT: Clean the Cylinder After Honing

It is very important that the cylinder be thoroughly cleaned

after honing to remove all grit material. Wash the cylinder in a

solvent, then in hot, soapy water. Use electrical contact cleaner

if necessary to clean these areas. Rinse thoroughly, dry with

compressed air, and oil the bore immediately with 4 Cycle

Lubricant to prevent the formation of surface rust. If cylinder

wearing or damage is excessive, it will be necessary to replace

the cylinder. Hone only enough to deglaze the outer layer of

the cylinder bore.

PISTON INSPECTION

1. Measure piston outside diameter at a point 7mm up from the

bottom of the piston at a right angle to the direction of the

piston pin.

2. Subtract this measurement from the maximum cylinder

measurement obtained earlier.

PISTON TO CYLINDER CLEARANCE

Std: 0.02-0.05 mm

Service Limit: 0.1 mm

3. Measure piston pin bore. Replace piston if out of round.

4. Measure piston pin O.D. Replace piston pin if out of round.

Содержание AT56-69E

Страница 6: ...GENERAL INFORMATION 1 3 COBRA 400 Model AT56 69E Model Number RF3RA56XXCTXXXXXX Engine Model V69C ...

Страница 35: ...MAINTENANCE 2 25 ...

Страница 45: ...CVT SYSTEM 3 4 CVT EXPLODED VIEW ...

Страница 56: ...ENGINE 4 3 ENGINE ILLUSTRATION ENGINE EXPLODED VIEW ...

Страница 57: ...ENGINE 4 4 ...

Страница 58: ...ENGINE 4 5 COOLING SYSTEM EXPLODED VIEW ...

Страница 59: ...ENGINE 4 6 OIL FLOW DIAGRAM ...

Страница 125: ...FUEL AND CARBURETOR 6 15 FUEL TANK SYSTEM ...

Страница 135: ...BODY SUSPENSION STEERING 7 6 SUSPENSION ...

Страница 142: ...BODY SUSPENSION STEERING 7 13 STEERING ...

Страница 151: ...BRAKES 8 6 FRONT BRAKE EXPLODED VIEW MASTER CYLINDER ...

Страница 196: ...ELECTRICAL 9 31 WIRE DIAGRAM ...