Technical manual ADITRAT

7

4.- Frequency of regenerations.

Being all the clips stretched (according to operation 1):

- Press as many clips as many days you want to realize the regeneration, consecutive or

alternate.

EXAMPLE: - Daily regeneration:

Press all clips.

- Alternate regeneration, every 3 days:

Press the first clip, leave the following two clips on the left stretched,

then press the next clip, and so on, until the clips are over.

- Once you have fixed all the clips, make coincide one of the ones you have pressed with the

signal (E) DAY, and you will activate a process of regeneration for that same day.

5.- Manual immediate regeneration:

- Make coincide one of the pressed clips of the wheel (H) with the signal (E) DAY.

- Turn the control (C) anticlockwise until the wheel (F) gets in contact with and presses the

drain valve stem (G), and you will immediately activate a process of regeneration.

- Do not forget to reset the hour of the programmer after manipulating it.

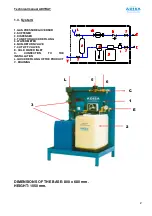

2.3.5. START UP.

As previously mentioned, the working pressure of the softener must be between 2 kg/cm

2

and 4

kg/cm

2

. * Check it.

A pressure lower than 2 kg/cm

2

does not allow obtaining correct brine suction, and an excessive

pressure risks to damage the valve or the salt suction system.

In case the pressure from the mains is higher than the maximum pressure recommended, it is

important to install a reducing pressure valve before the softener.

* Check the prefixed times in the programmer.

* Activate the phase of counter-washing to wash the resin in order to eliminate the dust and the

dirtiness that can be present in it. This operation can be realized by disconnecting the brine

suction pipe from the salt tank and then by activating the phase of slow washing during 20

minutes.

* Put the softener in the phase SERVICE.

* Then, check the operation of the other phases in the fixed times.

* At the end, once a complete regeneration has ended, check that the softener supplies water

with a hardness = 0ºF (the recommended hardness is 5ºF).

2.3.6. CHANGE OF INJECTOR.

In case the inlet pressure is not high enough to suck brine or, on the contrary, is too high for the

valve injector, it is recommended to change the latter. In order to regulate and make the suction

times more precise, act on the drain regulation valve.