8

exceed 930 W/ m³ of the room

Proper dimensions which let the installed device be at least 0,3 m from the walls of the room (

both sides and the back of the device), and the front minimum 1,2 m.

If the liquefied petroleum gas is used, the room must not be under the “0” level, that means in

the basement, and the temperature of the room where the GPB gas cylinder is placed must

not exceed 35 °C.

It is highly recommendable to install the fryer under a working extraction hood .

First steps

Before starting to assemble the fryer, make sure that all its parts are complete and have not been

damaged in transport.

1. Place the fryer in an easily accessible place, preferably a hard, non-flammable ground covered

with ceramic plates.

2. Level the fryer using the regulated legs.

3. Before connecting the fryer to the gas system:

- check the data plate to find out what kind of gas corresponds with the fryer installed and its gas

system ( propane-butane B/P or natural E gas GZ-50).

4. Connecting the device follow the rules from below:

- the natural gas GZ-50 should be installed stiffly using a pipe without intermittent weld (steel or

copper). In case of using elastic metal lead it must have CE Certificate

the liquefied petroleum B/P gas from the gas cylinder should be connected with the fryer

using an elastic hose. The hose must not be longer than 3m, have CE Certificate and its ends

should be secured with band clips.

Near any gas powered device, in an easily accessible place, there must be a gas inflow switch.

Check if there is no leakage in the connection between the gas system and the device

5. After connecting the device to the gas system, using proper sensors, check if there are any clefts

in the connections.

The device must not be operated if any clefts were detected.

3.

DESCRIPTION OF THE BURNER

The fryer is equipped with a set of burners which are composed of:

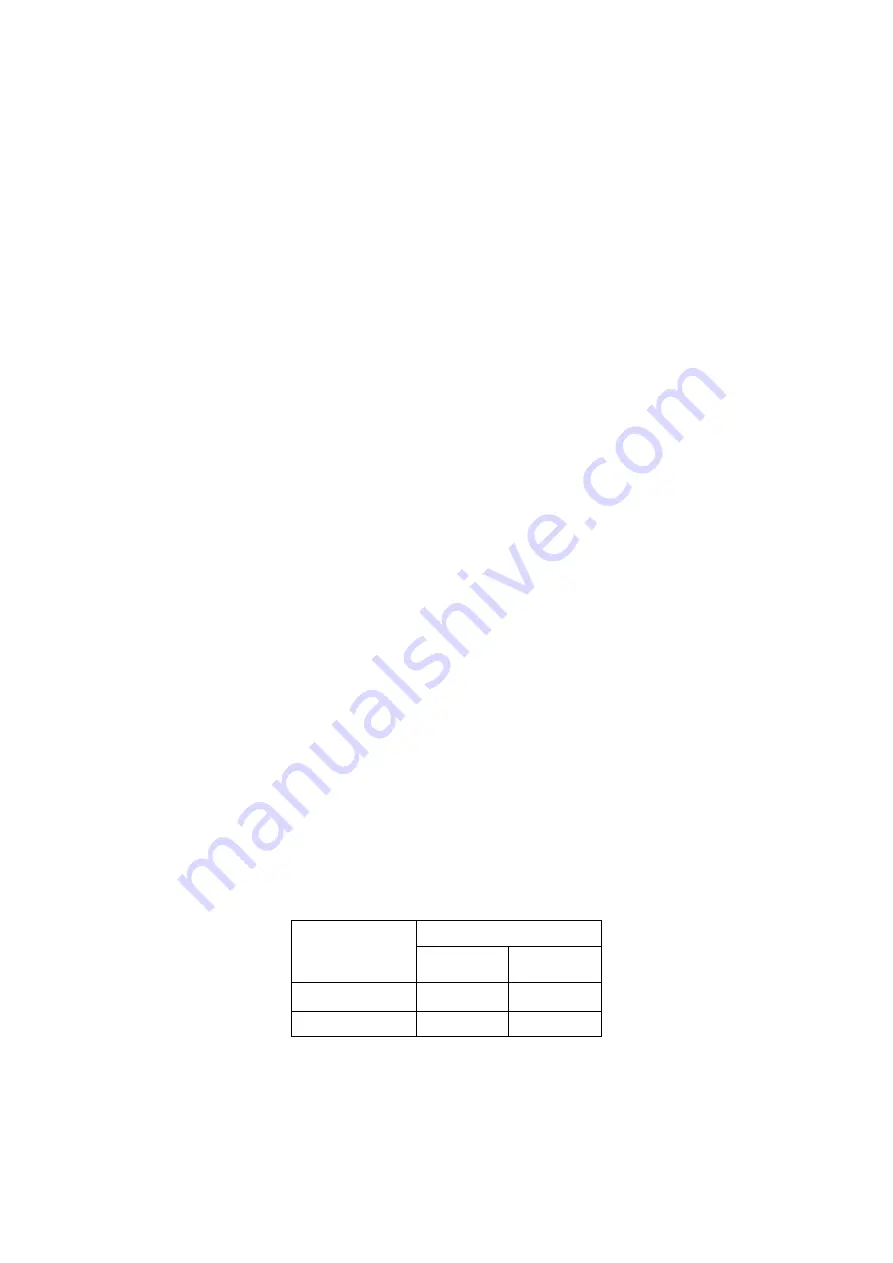

The main and the pilot burner equipped with a replaceable nozzle, illustrated in the frame

below:

BURNER

GAS

E(GZ 50)

B/P

Main 11 pcs.

0,80

2x0,4

Pilot 1 pcs.

0,30

0,25

starting electrodes

flame sensor (thermocouple)

oil temperature sensor

cut-off valve

Minisit 710

max. oil temperature limiter (220°C) (optionally)

Содержание ADA SCG 11

Страница 15: ...15...