7

TECHNICAL INSTRUCTION

intended for the installer

The fryer must be connected to the gas installation only by an authorized installer.

1. SUBASSEMBLIES DESCRIPTION

The pressure gas fryer is composed of the following sub assemblies:

Gas installation

The fryer can be connected to the B/P active gas installation through the gas reducing valve for

36 mbar or natural E gas (GZ50) and therefore it will be equipped ( consistently with the

order)with a proper gas connector pipe:

- with a crimped terminal for a liquefied petroleum gas installation used with the liquefied

petroleum gas GPB elastic hose.

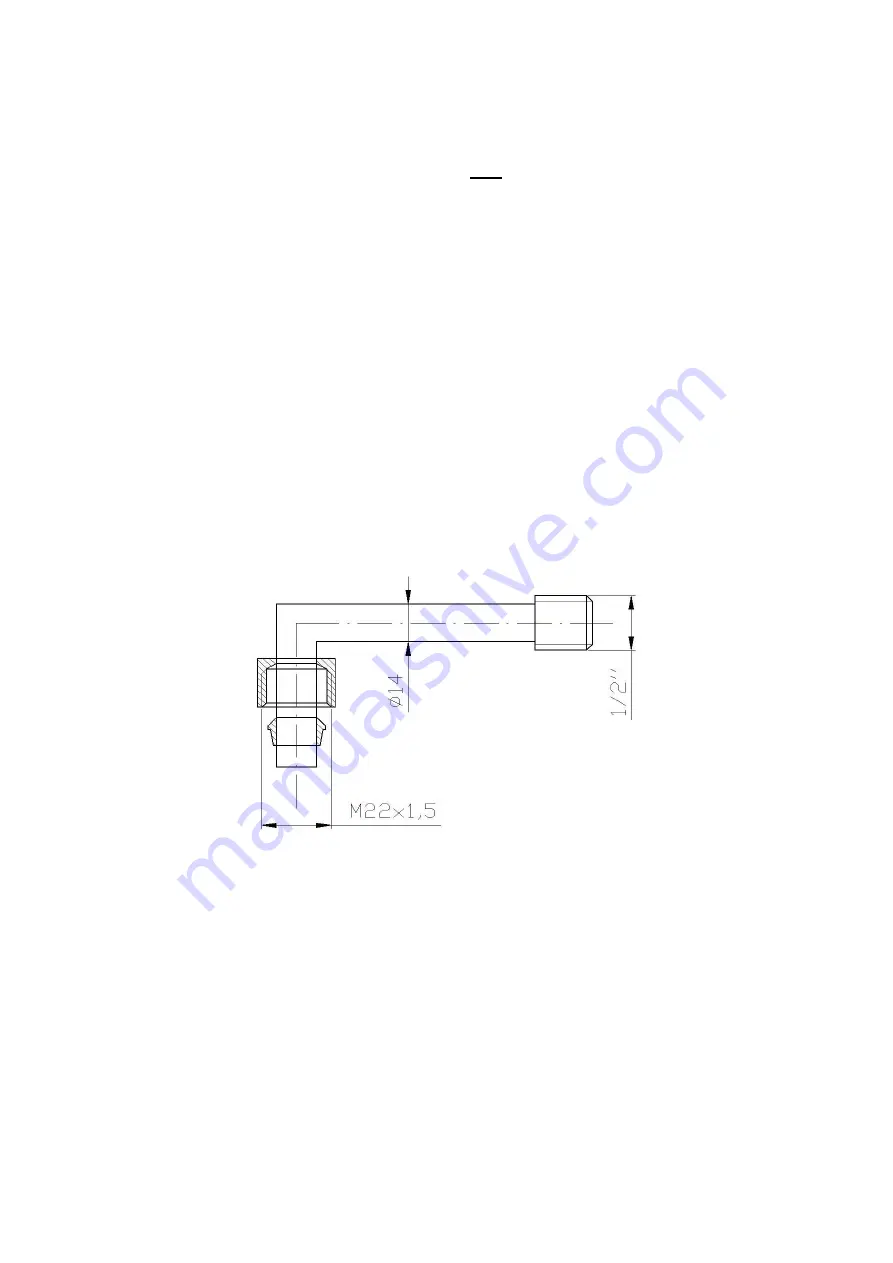

- with an external thread Rc ½ for the natural gas E ( GZ 50) ( according to the picture below)

The control/cut off valve Minisit 710 connected with a thermoelectromagnetic dust-proof

protection of the handset's burner,

Gas installation pipes.

External thread Rc ½ for the natural gas E

2.

THE FRYER ASSEMBLY

The room where the fryer is mounted should correspond to the building laws included in the order

of Minister of Infrastructure from 12.04.2002 concerned with the technical standards buildings

and their layouts should meet.

According to those standards such room should have:

a working supply-exhaust ventilation providing continuous air circulation, at least 37,5 m³/h

for each kilowatt of the gas device's thermal power.

The minimal dimension of the smoke conduit must not be smaller than 0,14 m , and the total

surface of the ventilating hood must not be smaller than 0,016 m²

Proper cubic capacity which provides that maximum heat coming from the gas devices will not

Содержание ADA SCG 11

Страница 15: ...15...