Installation and Commissioning Guide - Bulkhead 2 Split System

Doc. No. 9590-5011

Ver. 1 211217

18

Installation and Commissioning Guide

Bulkhead Split System

12. Wiring

Safety Precautions

DANGER

• Be sure to disconnect the power supply before working on the unit.

• All electrical wiring must be done according to local and national regulations.

• Electrical wiring must be done by a qualified technician. Improper connections may cause electrical malfunction, injury

and fire.

• Connect the power cable to the terminals and fasten it with the clamp.

• Make sure that all wiring is done correctly and the control board cover is properly installed. Failure to do so can cause

overheating at the connection points, fire, and electrical shock. Connect the outdoor wires before connecting the

indoor wires.

• Make sure you earth the unit. Improper earthing may cause electrical shock.

• DO NOT

connect the unit with the power source until all wiring and piping is completed.

• Make sure that you do not cross your electrical wiring with your signal wiring, as this can cause distortion and

interference.

Follow these instructions to prevent distortion when the compressor starts:

•

The unit must be connected to its individual sub-circuit. Ensure sub-circuit mains are of recommended size to ensure

minimal voltage drop at supply terminals.

•

No other equipment should be connected to the same sub-circuit as the A/C unit.

•

The unit’s power information can be found on the rating sticker on the product.

NOTE

Fuse Specifications

The air conditioner’s circuit board (PCB) is designed with a fuse to provide over current protection. The fuse specifications,

T5A/250VAC is printed on the circuit board

For the units with R-32 refrigerant , only the blast-proof ceramic fuse can be used.

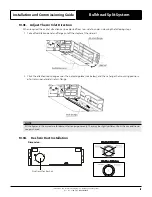

Indoor Unit Wiring

1. Prepare the cable for connection

a. Using wire strippers, strip the outer insulation from both ends of signal cable.

b. strip the insulation from the ends of the internal wires.

c. Using a wire crimper, crimp fork-lugs on the ends of the wires.

2. Remove the cover of the electric control box on your indoor unit.

3. Connect the fork-lugs to the terminals. Match the wire colours/labels with the labels on the terminal block, and firmly

screw the lug of each wire to its corresponding terminal. Refer to the Serial Number and Wiring Diagram located on

the cover of the electric control box.

4. Clamp down cable with the designated cable clamp to secure it in place. The cable should not be loose, and should

not pull on the lugs.

5. Reinstall the electric box cover.

CAUTION

• While connecting the wires, please strictly follow the wiring diagram.

• The refrigerant circuit can become very hot. Keep the interconnection cable away from the copper tube.