Direct Gas Make-Up Air

37

Start-Up: Direct Gas-Fired Heating

Optional Features

There are two important design features that must be

maintained by recirculating direct fired equipment.

Recirculated air cannot be passed over the burner

and airflow across the burner must remain constant

throughout the range of recirculation. These units with

recirculation meet both of these requirements and are

able to operate with up to 80% recirculated air.

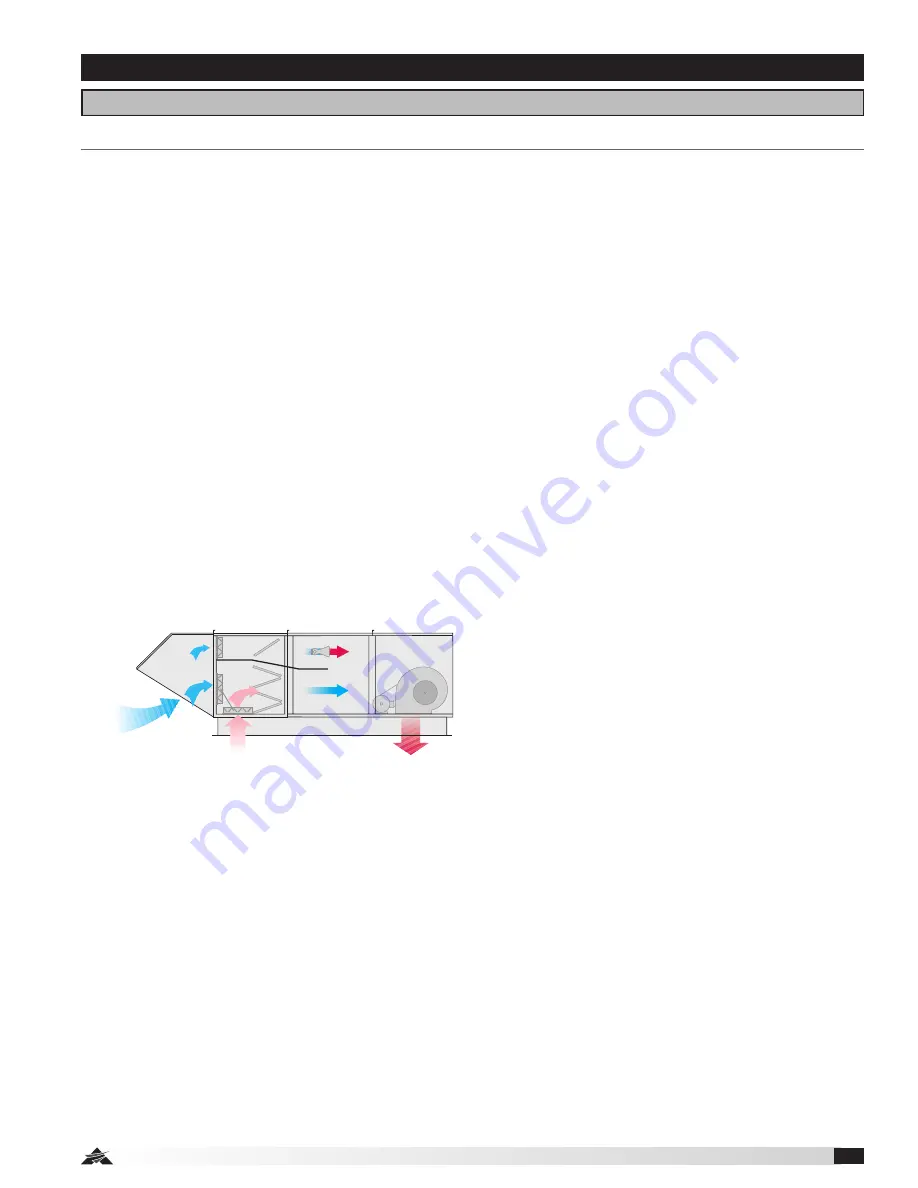

Recirculation with Filtered Return Air

Model XDGX is available with a recirculation design

that includes integral filtration of the recirculated air. In

this design, the inlet portion of the unit is divided into

two airstreams. The upper airstream carries 20% of

the total supply volume. This air enters the unit through

a damper, passes through filters, and then across the

burner where it is heated. The other 80% of the supply

air passes through the lower airstream which includes

a mixing box that controls the ratio of recirculated

and outside air that is introduced. The air in the lower

airstream passes through filters and is mixed with the

heated outside air that passed across the burner. A

bypass baffle is located under the burner in the bypass

airstream to allow adjustment of the percentage of total

supply air that is permitted to bypass the burner. This

baffle may need to be adjusted to achieve a proper

burner pressure differential.

Supply Air

Outside Air

(100-20%)

20%

80-0%

Recirculated Air

(0-80%)

Burner Pressure Differential Check

The burner pressure differential on direct fired units

with recirculation is affected by total airflow and the

percentage of airflow that is passing over the burner.

If too much air is allowed to bypass the burner, the

burner pressure differential will be too low. If too little

air is allowed to bypass the burner, the burner pressure

differential will be too high.

Reference the

Start-Up:

Direct Gas-Fired Heating,

All Units

section in this Installation, Operation and

Maintenance Manual for more information about

measuring burner pressure differential and adjusting

burner baffles. Before making any adjustments to the

burner baffles on a unit with recirculation, measure the

burner pressure differential with the recirculation damper

fully closed and again with the recirculation damper fully

open. The burner pressure differential will vary slightly

as the percentage of recirculated air varies. Verify that

the burner pressure differential is in the correct range

throughout the operating range of the recirculation

damper:

• Natural Gas: 0.5 to 0.8 in. wg

• Liquid Propane (LP) Gas: 0.7 to 1.0 in. wg

If adjustment is necessary, adjust the fan RPM via

adjustable motor sheaves (if equipped) or sheave

replacement to achieve proper burner pressure drop.

Motor amp draw must not exceed full load amperage

(FLA) on motor nameplate. If fan RPM cannot be

adjusted or proper burner pressure differential cannot

be achieved by adjusting fan RPM, adjust the baffle

located over the recirculated air damper (non-filtered

recirculation) or the baffle located under the burner in

the bypass airstream (filtered recirculation). Adjusting

the recirculated air damper baffles or bypass baffles

will adjust the percentage of air that is allowed to

bypass the burner. Close the baffle(s) to raise the

burner pressure differential. Open the baffle(s) to lower

the burner pressure differential. If the recirculated air

damper baffles or bypass baffle are adjusted as far

as they will go, adjust the baffles on either side of the

burner as necessary.

Recirculation Arrangements