Visit:

www.abisupport.com

18

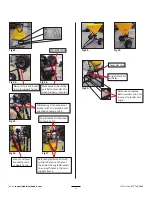

Maintenance

1.

Tire MAX inflation - 28 PSI. Replace tire if cracks or missing chunks in tire are present.

2.

Before beginning work:

A. Apply a thick layer of grease to all exposed moving parts.

B. Apply a film of biodegradable oil in crevasses and corners in order to keep corrosive

material from rusting areas that are difficult to clean.

3.

After each use:

A. Be sure to thoroughly wash the machine without using excessive pressure especially on the moving parts. It is

B. Carefully dry the machine.

C. Apply a thick layer of grease to all exposed moving parts.

D. Apply a film of biodegradable oil in crevasses and corners.

4.

After seasonal use it is important to perform the following for prolonged storage:

A. Wash and dry the spreader carefully.

B. Inspect the spreader and replace worn or damaged parts. If corrosive material has eaten under the paint,

clean off the area with a wire brush and touchup with primer and paint.

C. Tighten all hardware.

D. Apply a thick layer of grease to all exposed moving parts.

E. Apply a film of biodegradable oil in crevasses and corners.

F. Cover the spreader from the elements in order to have it in perfect condition for the start of the next season.

5.

The gearbox has been filled with EP grade grease from the factory. The grease never needs replacing unless internal

work is done to the gearbox.

6.

Inspect the entire machine periodically. Look for loose fasteners, worn or broken parts, and leaky or loose fittings. Use

T

ABLE 3 - TORQUE SPECIFICATIONS

for any loose bolts or nuts.

7.

Never replace hex bolts with less than grade five bolts unless otherwise specified (ex: shear bolts).

particularly important to wash the implement after using salt or fertilizer. This will help prevent the caustic

chemicals in the salt and fertilizer from destroying the metal of the machine.

TABLE 3 - TORQUE SPECIFICATIONS