9

1

1

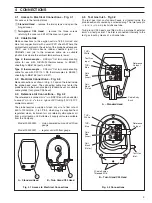

A – Standard Head

B – Twin Gland C95 Head

Cell–

Black

(Outer)

Cell+

Red

(Inner)

THC–

Blue

Test Gas

Input

THC+

White

Cable Entry

Bush

Reference

Air Input

2 Cable Entries

Threaded M16

Reference

Air Input

Test Gas

Inlet

A – Standard Head

B – Twin Gland C95 Head

Cell–

Black

(Outer)

Cell+

Red

(Inner)

THC–

Blue

THC+

White

4

CONNECTIONS

4.1

Access to Electrical Connections – Fig. 4.1

For access to the terminal block:

1

Standard Head

– remove the two screws and open the

hinged cover.

1

Twin-gland C95 Head

– remove the three screws

retaining the cover and lift off the cover and gasket.

4.2

Cable Details

Make connections to the oxygen cell via 16/0.2mm red and

blue twin copper braid with overall PVC sheath. Where the

ambient temperature in the vicinity of the probe head exceeds

100

°

C use 0.75mm

2

silicone rubber sheathed (part no.

YBM0614) and join to the screened cable via a suitable

junction box where the ambient temperature is lower.

Type K thermocouple

– 3/0.9mm

2

flat twin compensating

cable for use with NiCr/NiAl thermocouples to BS4937,

sheathing to BS6746 (part no. E35).

Type R thermocouple

– 3/0.9mm

2

flat twin compensating

cable for use with Pt/Pt 13% Rh thermocouples to BS4937,

sheathing to BS6746 (part no. E37).

4.3

Electrical Connections – Fig. 4.2

Make connections as shown in Fig. 4.2 and on the label inside

the probe head cover. The connecting cable must enter the

probe head via the bush provided (standard head) or suitable

cable glands (twin gland C95 head).

4.4

Reference Air Connections – Fig. 4.2

The reference air connector is

1

/

8

in. BSP fitted with an adaptor

to accept

1

/

4

in. i.d. x

3

/

8

in. o.d. nylon or PVC tubing (100

°

C/212

°

F

ambient maximum).

The probe requires a supply of clean, dry air at a flow rate of

500 to 1000ml/min. (1 to 2ft

3

/hr), which may be supplied from

regulated, clean, instrument air or preferably atmospheric air

from a small pump unit. Suitable air supply units are available

from the Company:

Model 003000240 – mains-powered pump unit with flow

gauge

Model 003000241 – regular unit with flow gauge.

4.5

Test Gas Inlet – Fig 4.2

The test gas inlet on standard heads is situated inside the

probe head and is sealed by a screwed plug. The inlet accepts

1

/

4

in i.d. x

3

/

8

in o.d. plastic/silicone tube.

Twin-gland C95 heads are fitted with a permanent external

6mm o.d. test gas inlet. The inlet is connected internally to the

test gas input by means of a silicone tube.

Fig. 4.1 Access to Electrical Connections

Fig. 4.2 Connections