2

e

b

o

r

P

n

e

g

y

x

O

a

i

n

o

c

r

i

Z

2

P

G

Z

2

P

G

Z

/

X X X X X

h

t

g

n

e

l

n

o

i

t

r

e

s

n

I

m

m

0

0

6

m

m

0

0

0

1

l

a

i

c

e

p

S

1

2

9

e

l

p

u

o

c

o

m

r

e

h

T

R

e

p

y

T

3

t

P

7

3

9

4

S

B

h

R

%

3

1

t

P

/

t

P

K

e

p

y

T

4

t

P

7

3

9

4

S

B

l

A

i

N

/

r

C

i

N

l

a

i

c

e

p

S

1

2

9

h

t

a

e

h

S

)

d

r

a

d

n

a

t

s

(

n

i

a

l

e

c

r

o

P

s

u

o

n

i

m

u

l

A

0

0

8

y

o

l

o

c

n

I

l

a

i

c

e

p

S

1

2

9

g

n

i

t

n

u

o

M

e

g

n

a

l

F

1

d

a

e

H

r

o

t

c

e

n

n

o

C

d

r

a

d

n

a

t

S

5

9

C

e

p

y

T

d

n

a

l

G

n

i

w

T

0

1

2

PREPARATION

2.1

Unpacking

Warning.

The probe contains refractory ceramic

fibres. Inhalation of fibre or dust particles should be

avoided. If the probe is dismantled or damaged in service,

the materials of construction are NOT classified as

Hazardous Waste and may be disposed of at tipping sites

for Industrial waste.

Caution.

The probe is very fragile. Unpack and

handle with care.

Each probe is despatched with its components individually

placed within a common pack. Retain this pack to facilitate

return of the probe to the manufacturer if necessary. Remove

the probe from its packing as follows:

a) Place the polystyrene pack, top uppermost, on a flat

surface and cut the tapes holding the two halves together.

b) Carefully lift the top half of the pack, to gain access to the

probe components which are individually located within the

bottom half.

c) When removing the components from the pack take great

care to support the terminal head and not to twist or bend

the electrode assembly attached to it.

d) Re-assemble the packing for future use.

✶

Note.

If for any reason a non-standard sheath is

fitted adjust the diameter of the wadding at the end of the

probe to allow a snug fit.

To reduce its diameter the wadding may be compressed

slightly.

To increase its diameter, apply slight end pressure on the

wire bonding at both ends of the wadding. Mould the

wadding by hand to ensure a light push fit into the sheath.

2.2

Checking the Code Number

Ensure that the correct equipment is being installed – check

the code number on the probe against

Table 2.1 below. Code

number labels are fitted inside the probe head.

2.3

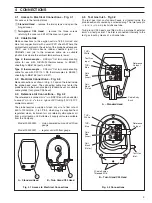

Assembling the Probe – Fig. 2.1

Caution.

Take care to avoid damage to the probe

when fitting the sheath assembly.

1

Drill the fixing flange to suit the local fixing requirements.

2

Push the three long countersunk-head screws through the

fixing flange and secure them in position with the three lock

nuts.

3

Position the clamp ring over the boss on the probe head,

ensuring correct orientation of the ring’s centre taper.

4

Position the sealing ring over the boss, ensuring that it

locates correctly in the centre taper.

5

Carefully insert the probe into the ceramic sheath ensuring

that the wadding at the probe end is not damaged and that

the filter washer is in position at the end of the sheath.

6

Secure the sheath to the boss with the three cheesehead

screws.

7

Slide the fixing flange over the sheath, ensuring that it is

seated over the locating step.

8

Locate the clamp ring over the three screws on the flange

2

and secure using three nuts. Tighten the nuts down

equally so that the fixing flange is pulled tightly against the

locating step on the sheath and the sealing ring is

compressed until the adjacent faces of the clamp ring and

sheath are 1 to 1.5mm apart. Use a 1mm drill or shim to set

the gap correctly.

Table 2.1 Checking the Code Number