47

Check the following conditions individually:

• With the circuit-breaker closed, insertion of

the withdrawable part towards the service

position must be blocked after only half a turn

of the crank in the clockwise direction, and

the travel motor on motor-operated

withdrawable parts must not be capable of

being switched on.

• With the earthing switch closed, insertion of

the withdrawable part towards the service

position must be blocked after only two

clockwise turns of the crank, and the travel

motor on motor-operated parts must not be

capable of being switched on.

Do not use force

(max. torque 25 Nm)!

2. The withdrawable part must only be movable

from the service position into the test/

disconnected position with the circuit-breaker

open.

Check this condition as follows:

• With the circuit-breaker closed, withdrawal

movement of the withdrawable part must be

blocked after only half a turn of the crank in

the anti-clockwise direction, and the travel

motor on motor-operated withdrawable parts

must not be capable of being switched on.

3. Closing of the circuit-breaker must only be

possible when the withdrawable part is in the

defined test/disconnected position or service

position.

The control wiring plug 8.1 must previously have

been inserted.

Check this condition as follows:

• It must not be possible to close the circuit-

breaker with the withdrawable part in any

position between the test/disconnected

position and the service position.

• Enabling of switching when the withdrawable

part moves into the service position is

effected electrically by operation of auxiliary

switch -S6 in the breaker housing (for type A),

or of auxiliary switch -S9 in the withdrawable

assembly (for type B), and mechanically

slightly earlier; the latter corresponds to a

position approximately half a turn of the crank

before stop.

• For motion into the test/disconnected

position, the same enabling conditions apply

analogously, in this case by means of auxiliary

switch -S6 in the breaker housing(for type A)

or the auxiliary switch -S8 in the withdrawable

assembly (for type B).

4. It must only be possible to open the circuit-

breaker (manually) when the withdrawable part

is in the service position or test/disconnected

position and the control voltage has failed.

Check this condition.

5. Withdrawable parts with order-related blocking

magnet -Y0 may not be moved in case of control

power failure, or when there is no control power.

Do not forcibly move blocked withdrawable

parts! The blocking magnet -Y0 is only present

on manually operated withdrawable parts.

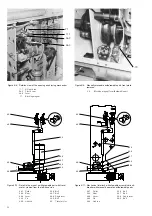

Releasing the blocking magnet -Y0.

• Remove front plate 9.2,

• Disengage blocking magnet -Y0 by pulling the

magnet armature,

• While doing so, turn crank 5 about one half

turn (either direction of rotation is permissible).

The blocking magnet is only active in the test

position and service position. In intermediate

positions it has no effect.

6. Disconnection of the control wiring plug 8.1 as

well as later insertion must be blocked in the

withdrawable part’s service position.

Check this condition.

8.6

Spare parts, auxiliary materials, lubricants

8.6.1

Spare parts

When parts are required, the serial number of the

relevant withdrawable breaker part or circuit-

breaker should always be quoted. Setting

instructions are to be requested separately.

Circuit-breaker VD4:

• Shunt release, auxiliary switch:

For notes on settings see drawing

GCE 717 96 11

• Charging motor with gearbox:

No special notes required

(table 1)

Withdrawable assembly of VD4:

• Manually moveable withdrawable assembly :

– type A:

For notes on settings see drawing

GCE 7003570, sheet 1 and 2

– type B:

For notes on settings see drawing

GCE 7003570, sheet 1 and 2.

• Motor-driven withdrawable parts:

For notes on settings see drawing

GCE 7003571

• Blocking magnet -Y0:

For notes on settings see drawing

GCE 7003820, sheet 1.

(table 2)

Содержание VD4 Series

Страница 2: ......

Страница 55: ...ABB Connect ABB Connect ABB ABB ABB Connect iOS Android Windows 10...