6

Introduction to the manual

3ADW0005Q964 E-Stop cat.1 without opening mains contactor en b

Abbreviations

Abbreviations used in this manual are listed below.

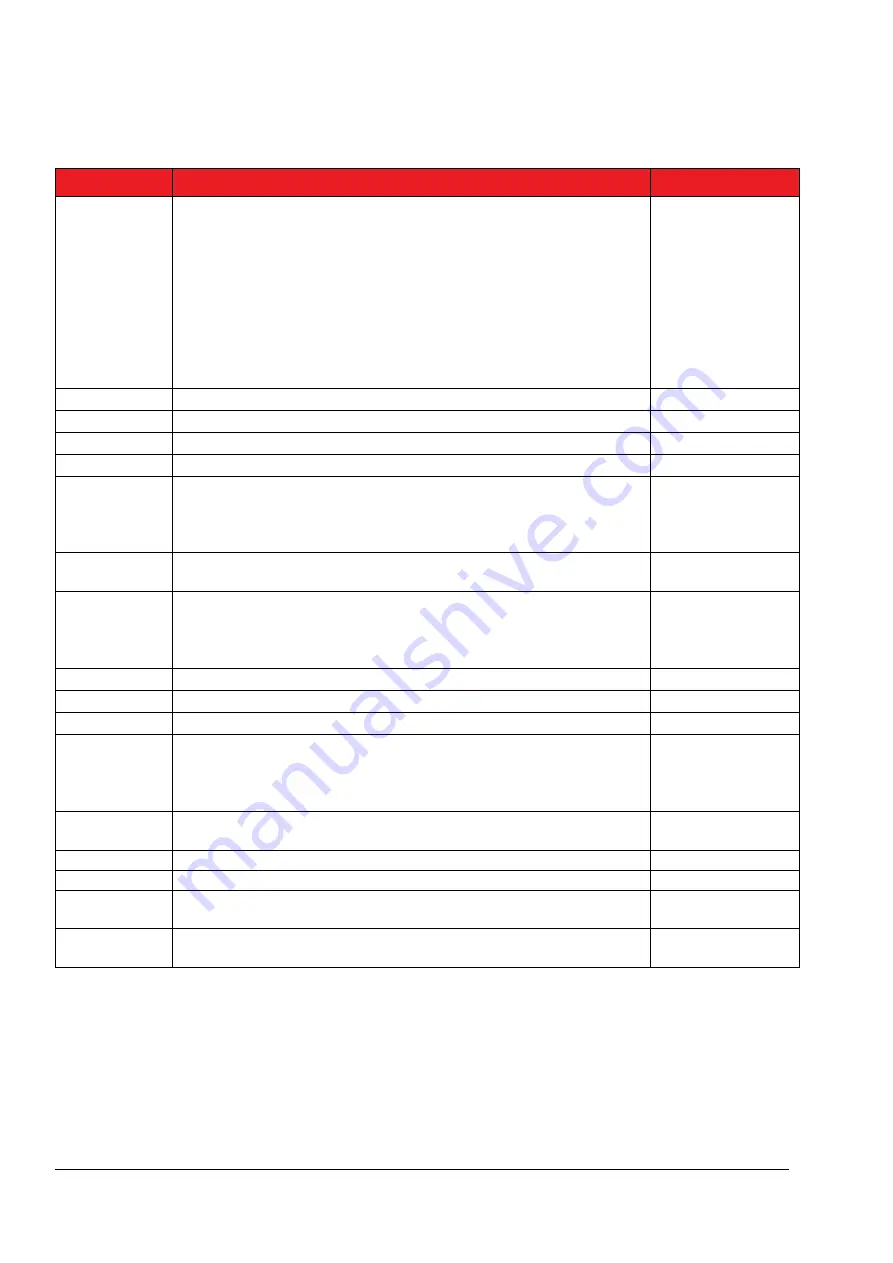

Abbreviation

Description

Reference

Cat.

Category

1. Stop category according to EN/IEC 60204-1

The stop categories are: 0 (uncontrolled stop) and 1 (controlled

stop)

2. Classification of the safety-related parts of a control system in

respect of their resistance to faults and their subsequent

behavior in the fault condition, and which is achieved by the

structural arrangement of the parts, fault detection and/or by

their reliability.

The categories are: B, 1, 2, 3 and 4.

EN/IEC 60204-1

EN ISO 13849-1

CCF

Common cause failure (%)

EN ISO 13849-1

DC

Diagnostic coverage

EN ISO 13849-1

DI

Digital input

E-stop

Emergency stop

Frame (size)

Relates to the construction type of the drive in question. For

example, several drive types with different power ratings can

have the same basic construction, and a frame size is used in

reference to all those drive types.

HFT

Hardware fault tolerance

IEC 61508,

EN/IEC 62061

PFH

Probability of dangerous failures per hour

IEC 61508,

EN ISO 13849-1,

EN/IEC 62061,

EN/IEC 61800-5-2

PL

Performance level (levels are: a, b, c, d and e). Corresponds to SIL. EN ISO 13849-1

RO

Relay output

SC

Systematic capability

IEC 61508

SIL

Safety integrity level

IEC 61508,

IEC 61511,

EN/IEC 62061,

EN/IEC 61800-5-2

SILCL

Maximum SIL that can be claimed for a safety function or

subsystem

EN/IEC 62061

SS1

Safe stop 1

EN/IEC 61800-5-2

STO

Safe torque off

EN/IEC 61800-5-2

T

1

Proof test interval or lifetime (the smaller one)

IEC 61508,

EN/IEC 62061

Off3

Function in Drive: Emergency stop with configurable

deceleration time according to Cat. 1.

Profibus standard

Exclusion of liability

ABB is not responsible for the implementation, verification and validation of the overall safety system.

It is the responsibility of the system integrator (or other party) who is responsible for the overall system

and system safety. The system integrator (or other responsible party) must make sure that the entire

implementation complies with all relevant standards, directives and local electrical code, and that the

system is tested, verified and validated correctly.