2105824-001 rev. AA

| 9

4. Remove the wires from the connector(s). If two connectors were removed, keep

for rewire.

5. Hold the existing board by the edges, and pull it out slowly.

6. Unplug the 16-pin connector at the bottom of the board to detach the board from

the sensor assembly inside the casing.

7. Place the removed board in a safe place (protect from static

electricity).Connection to the board is required to obtain configuration.

8. Unscrew the conduit to detach from enclosure. Leave wire ends hanging.

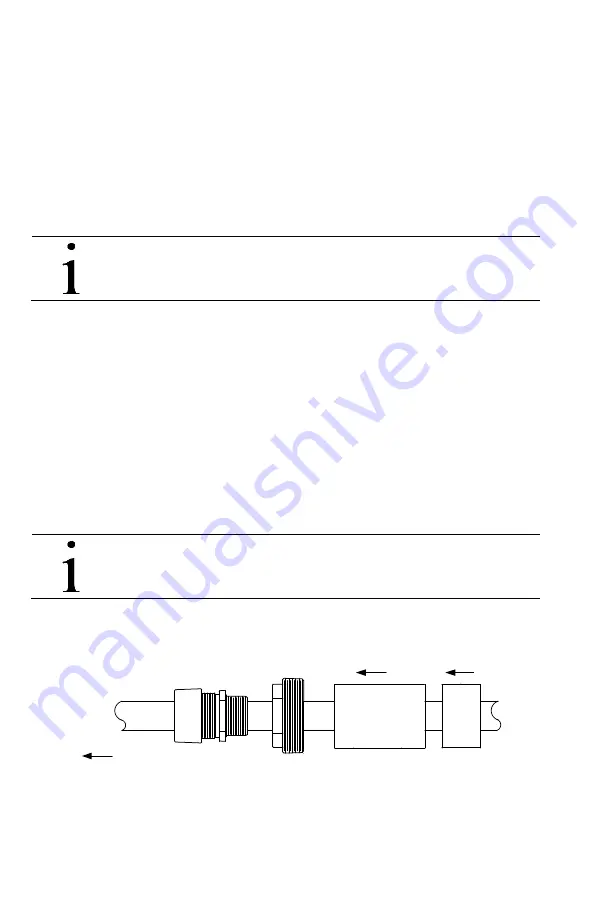

9. Replace the cover on the electronics enclosure.

10. Loosen the nut on the cord connector.

IMPORTANT NOTE:

There should be no cord connector on high

pressure units.

11. Unscrew the tank port bushing.

12. Remove the LevelMaster from the tank and lay it on the ground using the

wooden blocks underneath for support (If no wooden blocks are available use

any stable and even support to keep the unit from rotating while in horizontal

position).

13. Proceed to replace the existing floats.

4.2 Replace the existing floats

To replace existing floats:

1. Remove the float clamp from the bottom of the casing.

2. Slide the float(s)

off the bottom of the casing.

3. Slide the new float(s) onto the bottom of the casing. If using two floats, install in

the correct order (Figure 3).

IMPORTANT NOTE:

Position the float(s) correctly so that the text on

the float label would be in the upright position when the LevelMaster is

inserted back into the tank.

a. Install the oil level float first.

b. Install the water level float second.

OIL

FL

OAT

WAT

E

R

FL

OAT

1

2

TOP OF

LEVELMASTER

Figure 3: Positioning the floats for dual float configuration

4. Slide the float clamp back onto the bottom of the casing.

5. Use a Phillips screwdriver to tighten the clamp 1 inch above the bottom of the

casing. Considerable force may be required to lock the clamp on tight.

Содержание LevelMaster 7100

Страница 26: ...26 2105824 001 rev AA Figure 20 Measurement errors...

Страница 27: ...2105824 001 rev AA 27 Notes...