28

AQUA M A STE R4

|

EL EC T R O M AG N E T I C FLO W M E T ER I N SER T I O N SEN S O R | O I/FE W4 0 0/A P - EN R E V. B

…Appendix

Velocity profiles background

The Point of Mean Velocity is on the knee of the curve (the

velocity at this point is changing rapidly with distance) so it is

necessary to position the insertion sensor extremely accurately

in order to measure the correct velocity. If the insertion sensor

is inserted accurately to 72.5 mm, it is therefore measuring the

mean velocity of 1.722 m/s which, when multiplied by the area,

gives a volume flow of 487 l/s. If the insertion sensor is inserted

to 74 mm instead of 72.5, the velocity measurement is 1.85 m/s

instead of the expected 1.722. Multiplying this figure by the

area results in a volume flow of 523 l/sec – an error of 7.4 %.

On-site it can be very difficult to locate a insertion sensor

exactly, so this sort of error is quite common. With insertion

sensors other than this insertion sensor, working under any

degree of pressure in the line, inserting a insertion sensor to

within 10 mm of its intended location is often accepted. Using

the calculation above, this produces an error of approximately

15 %. This can be reduced significantly by using the following

method.

Referring to Figure 28, in the middle of the pipe, near the center

line, the profile is relatively flat, i.e. the flow velocity does not

change very much with distance into the pipe. Therefore, if the

velocity is measured on the center line, measurement errors

due to positional errors (i.e. not locating the insertion sensor

where required) are very small; hence most users will try to use

the center line measuring position. However, as explained

previously, this process gives us the wrong answer, Fortunately

there is a mathematical relationship between the velocity at the

center line and the mean velocity within the pipe – the Profile

Factor (F

ρ

).

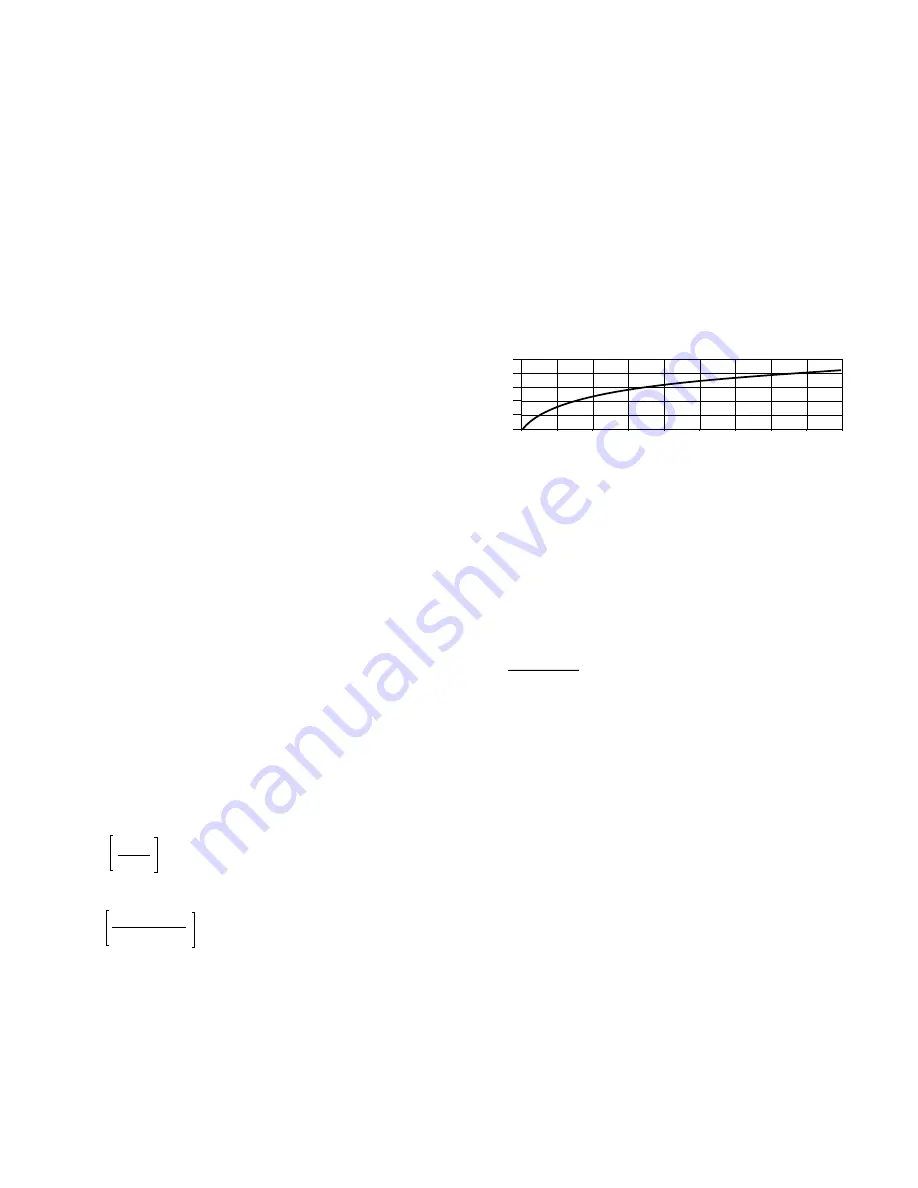

The value of F

ρ

can be calculated by an equation (below) or

obtained from a graph – see Figure 29.

F

ρ

is calculated as follows:

where:

and:

n = 1.66log(Re)

and:

D

Re =

–

ρν

µ

key

:

D = pipe diameter

ρ

= fluid density

ν

= average fluid velocity

µ

= fluid viscosity

Pipe bore in mm

Pipe bore in inches

P

ro

fi

le f

ac

to

r (

F

p

)

200

400

600

800

1000

1200 1400

1600

1800

2000

8

0.875

16

24

32

40

48

56

64

72

80

0.870

0.865

0.860

0.855

0.850

Figure 29 Profile factor vs flow velocity for pipe sizes

200 to 2000 mm (8 to 78 in)

When the insertion sensor insertion position is determined, the

effect of putting the insertion sensor into the pipe (see page

27) must be calculated.

The blockage or insertion effect is termed the

Insertion Factor

(Fi)

. This is a mathematical relationship and can be calculated

from the formula:

Testing the flow profile for symmetry

If there is any doubt as to the symmetry of the flow profile (see

page 10), a Partial Velocity Traverse must be carried out.

This procedure involves comparing the value of velocity at two

points at equal distances from the center line.

It is normal to compare the flow velocities at insertion depths

of 1/8 and 7/8 of the pipe diameter as these points are always on

the 'knee' of the profile.

Partial velocity traverse

Determine the internal diameter D of the pipe, in millimeters, by

the most accurate method available. If the insertion sensor

insertion length is greater than the internal diameter of the

pipe, proceed with the Single Entry Point Method. If the

insertion sensor’s insertion length is less than the internal

diameter of the pipe, proceed with the Dual Entry Point

Method.

F 1

(r – Yb)

r

=

–

–

1

n

ρ

Y

b

r

(n + 1) (2n + 1)

2n

=

2

F

i

=

1

1 – (38/(

π

D))