AQUA M A STE R4

|

EL EC T R O M AG N E T I C FLO W M E T ER I N SER T I O N SEN S O R | O I/FE W4 0 0/A P - EN R E V. B

27

Velocity limitations

IMPORTANT NOTE

See also page 25 for maximum flow values for

insertion sensor

.

All insertion sensors are susceptible to the vortex shedding

effect that can cause severe vibration of the insertion sensor,

resulting in damage and/or measurement instability.

Electromagnetic devices with no moving parts, such as the

insertion sensor, are less susceptible to this effect than

mechanical devices.

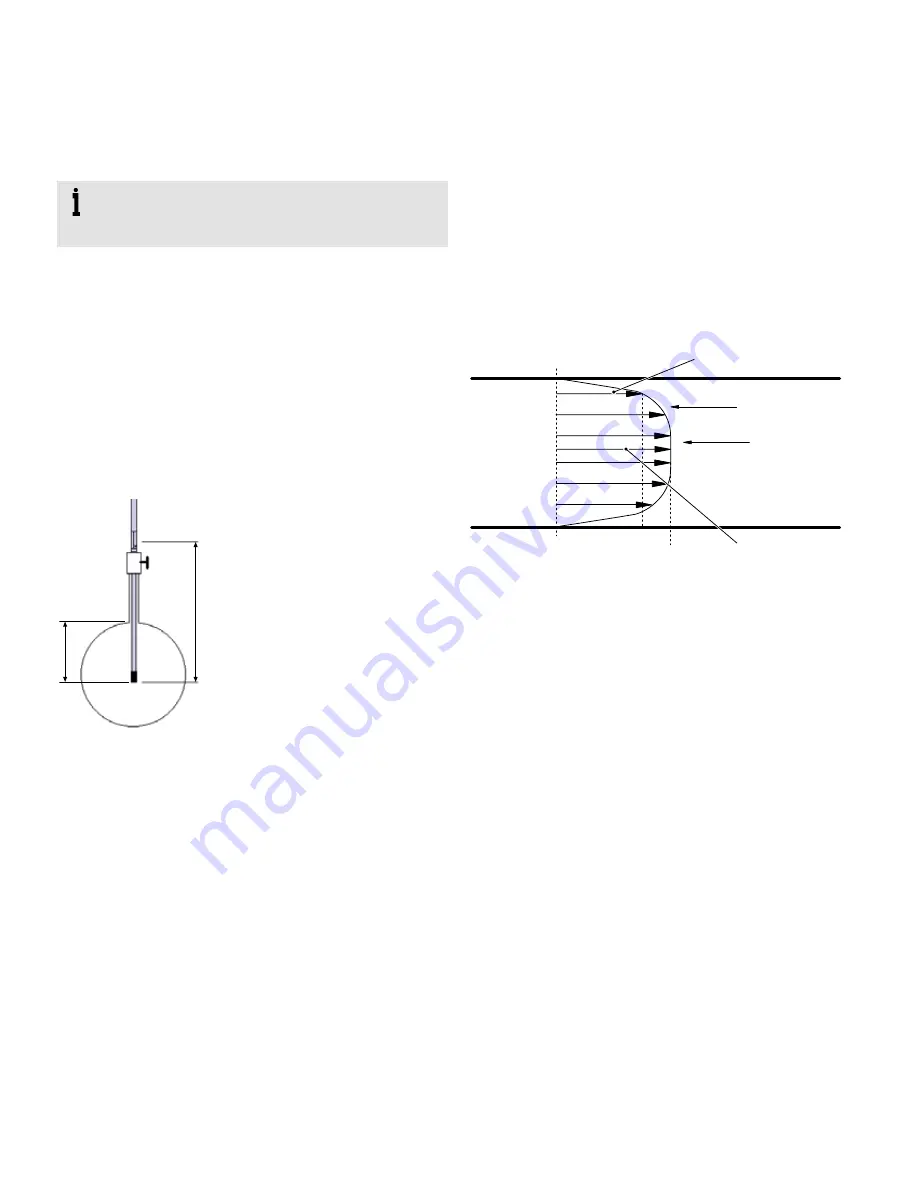

Figure 27 shows the maximum permissible velocities,

depending on the insertion sensor's location. This information

is provided as a guide only. Some installations may experience

unwanted vibration resonance that may further limit the

maximum velocity at which the insertion sensor can be used.

Insertion

length

Effective

insertion

sensor

length

Figure 27 Maximum permissible velocity for different pipe sizes

It is important to add the external length from the fixing point

to the insertion length. Failure to do this can give incorrect

information from the graphs, resulting in vortex shedding

affecting the insertion sensor.

Examples:

• A 600 mm (24 in) pipe with the insertion sensor mounted

on the center line has an insertion length of 300 mm (12 in).

• A typical valve is approximately 250 mm (10 in) high and the

distance to the support point inside the insertion sensor is

approximately 100 mm (4 in) therefore, in this example, the

total effective length is 650 mm (26 in).

• Max velocity at 650 mm is 3.6 m/s.

Velocity profiles background

Figure 28 shows a fully-developed turbulent profile of the flow

within a pipe. Such diagrams illustrate the distribution of flow

within the pipe. Known as the Flow Profile, it is highest in the

center falling to zero at either side on the pipe wall. If there is

sufficient upstream straight pipe, it can be assumed that there

is a profile of this form. In this case if, for example, the pipe is

600 mm in diameter, the velocity at the center line is 2 m/s and

the flow is 487 l/s

Mean velocity factor

Max. velocity

factor

Rapidly changing

velocities

Flat part

of curve

1.722 m/s

2.00 m/s

Figure 28 Turbulent flow profile

As the volume flow is known, the mean velocity in the pipe can

be calculated – note that it is actually 1.722 m/sec lower than

the velocity measured on the center line. Careful Investigation

of this profile or vector diagram reveals that the mean velocity

of 1.722 m/sec occurs at a point 72.5 mm or 1/8

th

of the pipe's

diameter in from the edge of the pipe. This point is referred to

as the Point of Mean Velocity (for a fully developed turbulent

flow profile only). This is true (provided the profile is turbulent

and fully developed) for all pipes of all sizes and at all flow rates,

and is recognized in the British Standard referred to previously.

Therefore, the best position to measure velocity is at the Point

of Mean Velocity, i.e. 1/8

th

of the diameter in from the edge of

the pipe. By placing the insertion sensor at this point a

straightforward calculation of volume flow can be performed –

but there is more to be considered.