Fault tracing

292

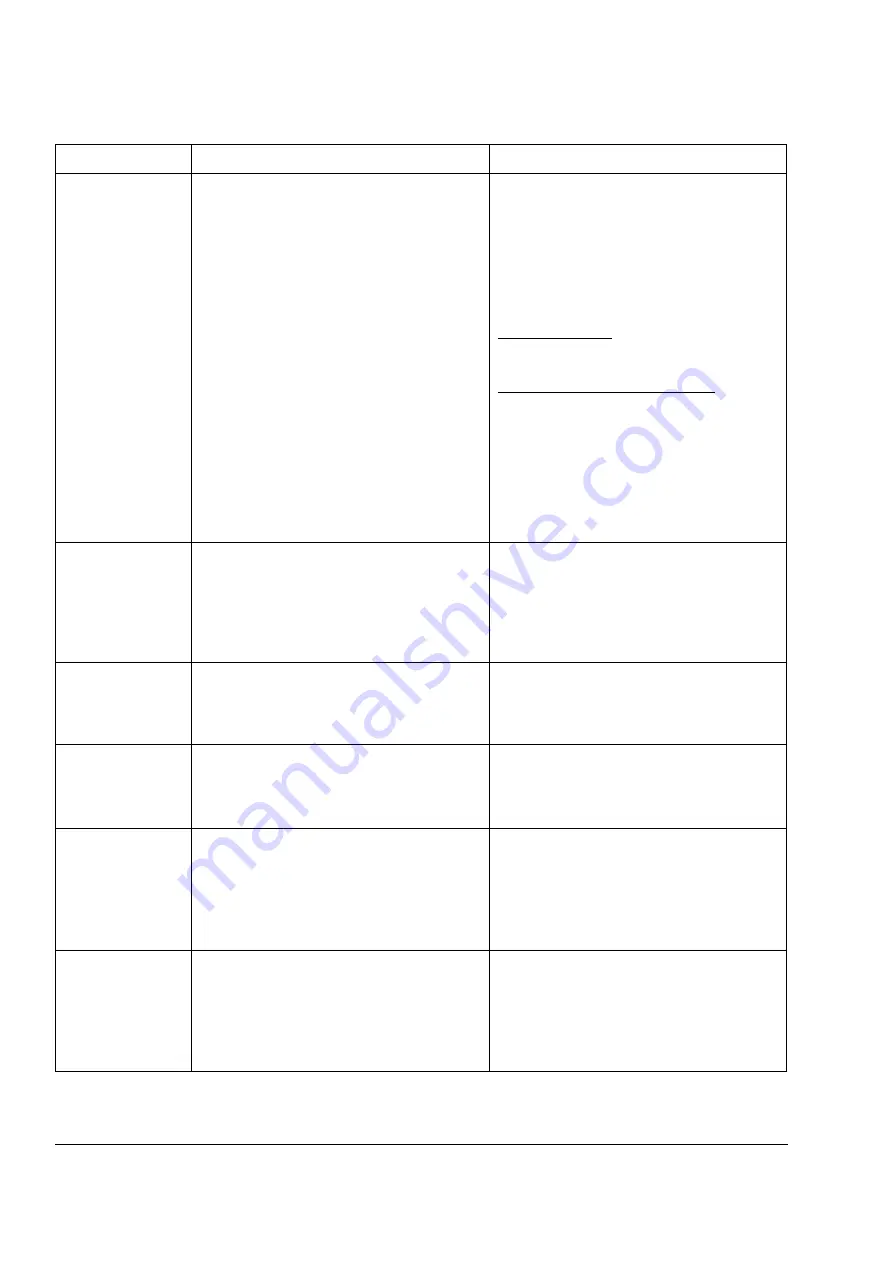

INV OVERTEMP

(4290)

3.17 FW 5 bit 13

Converter module temperature is excessive.

Check ambient temperature. If it exceeds

40°C, ensure that load current does not

exceed derated load capacity of drive. See

appropriate hardware manual.

Check that ambient temperature setting is

correct (parameter

).

Check converter module cooling air flow and

fan operation.

Cabinet installation: Check cabinet air inlet

filters. Change when necessary. See

appropriate hardware manual.

Modules installed in cabinet by user: Check

that cooling air circulation in cabinet has been

prevented with air baffles. See module

installation instructions.

Check inside of cabinet and heatsink of

converter module for dust pick-up. Clean when

necessary.

Reset and restart after problem is solved and

let converter module cool down.

I/O COMM ERR

(7000)

3.06 FW 2 bit 6

Communication error on control board,

channel CH1

Electromagnetic interference

Check connections of fibre optic cables on

channel CH1.

Check all I/O modules (if present) connected to

channel CH1.

Check for proper earthing of equipment. Check

for highly emissive components nearby.

LINE CONV

(FF51)

Fault on line side converter

Shift panel from motor side converter control

board to line side converter control board.

See line side converter manual for fault

description.

MOTOROVER

SPD

(FFF0)

3.33 CRANE FW bit 0

The speed exceeds the MOT OVERSPEED

LEV (Par.

)

Check Torque and Current limit settings

Check motor and motor cables

Check pulse encoder connections if used

MOTOR PHASE

(FF56)

3.06 FW 2 bit 15

(programmable

Fault Function

One of motor phases is lost due to fault in

motor, motor cable, thermal relay (if used) or

internal fault.

Check motor and motor cable.

Check thermal relay (if used).

Check Fault Function parameters. Disable this

protection.

MOTOR TEMP

(4310)

3.05 FW 1 bit 6

(programmable

Fault Function

…

Motor temperature is too high (or appears to be

too high) due to excessive load, insufficient

motor power, inadequate cooling or incorrect

start-up data.

Check motor ratings and load.

Check start-up data.

Check Fault Function parameters.

FAULT

CAUSE

WHAT TO DO

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...