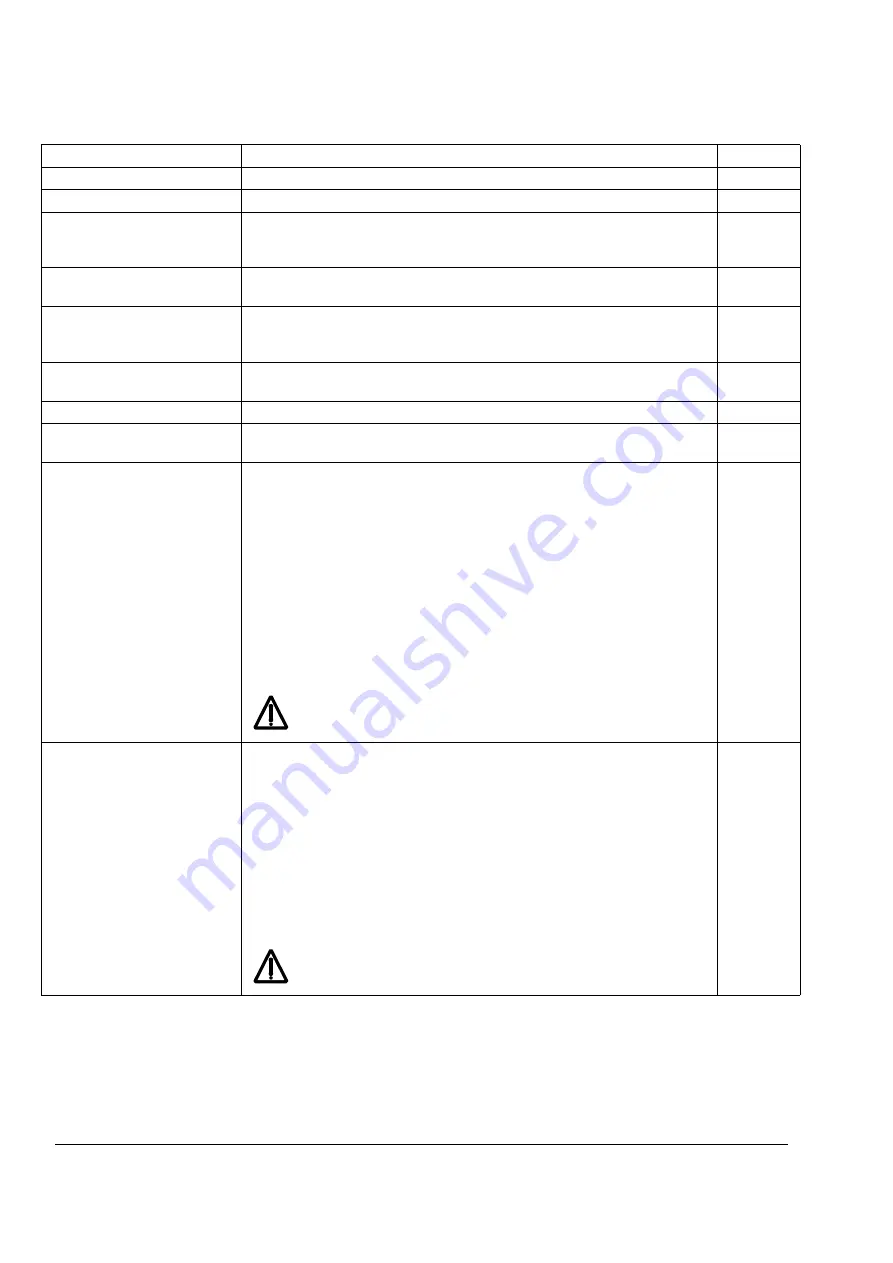

Actual signals and parameters

188

30.03

EXTERNAL FAULT

Selects an interface for an External fault signal.

NOT SEL

Inactive

1

PAR 30.24

External fault indication is given through pointer value in Par.

0: Fault trip. Motor coasts to stop.

1: No External fault.

2

30.04

MOTOR THERM

PROT

Selects how the drive reacts when the motor overtemperature is detected by

the function defined with parameter

FAULT

The drive generates a warning when the temperature exceeds the warning

level (95% of the allowed maximum value). The drive trips on a fault when the

temperature exceeds the fault level (100% of the allowed maximum value).

1

WARNING

The drive generates a warning when the temperature exceeds the warning

level (95% of the allowed maximum value).

2

NO

Inactive

3

30.05

MOT THERM P

MODE

Selects the thermal protection mode of the motor. When overtemperature is

detected, the drive reacts as defined with parameter

.

DTC

The protection is based on the calculated motor thermal model. The following

assumptions are used in the calculation:

- The motor is at the estimated temperature (value of

MOTOR

TEMP EST saved at power switch off) when the power is switched on. With the

first power switch on, the motor is at the ambient temperature (30 °C).

- The motor temperature increases if it operates in the region above the load

curve and decreases if it operates below the curve.

- The motor thermal time constant is an approximate value for a standard self-

ventilated squirrel-cage motor.

It is possible to finetune the model with parameter

.

Note:

The model cannot be used with high power motors (parameter

is

higher than 800 A).

WARNING!

The model does not protect the motor if it does not cool

properly due to dust and dirt.

1

USER MODE

The protection is based on the user-defined motor thermal model and the

following basic assumptions:

- The motor is at the estimated temperature (value of

MOTOR

TEMP EST saved at power switch off) when the power is switched on. With the

first power switch on, the motor is at the ambient temperature (30 °C).

- The motor temperature increases if it operates in the region above the motor

load curve and decreases if it operates below the curve.

The user-defined thermal model uses the motor thermal time constant

(parameter

) and the motor load curve (parameters

,

). User tuning is typically needed only if the ambient temperature differs

from the normal operating temperature specified for the motor.

WARNING!

The model does not protect the motor if it does not cool

properly due to dust and dirt.

2

Index

Name/Selection

Description

FbEq

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...