5

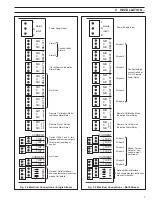

Sample Outlets

to Monitor

Stream Selection

Valves

Sample Inlet Tubes –

Streams 1, 2 and 3 respectively

Clean Drain

Tubes

Stream Selection

Valves

Out of Sample

Float Switches

Constant Head

Assembly

Sample Outlet to Monitor

Sample Inlet Tubes –

Streams 4, 5 and 6 respectively

A – Single Stream Connections

B – Configuration of Multi-Stream Constant Head Units

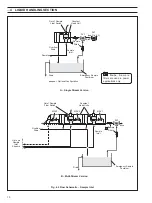

Feed the reagent tubes through the

grommet, at the left hand rear corner

of the case, from beneath. Fit them

to the appropriate connectors (red to

red, and so on).

Push the drain tube (9mm i.d.)

onto the external tube hose

connector.

Push the sample inlet tube (6mm i.d.)

onto the constant head sample inlet

tube hose connector (the smaller of the

two tube connectors).

Push the clean drain tube (9mm i.d.)

onto the constant head clean drain tube

hose connector (the larger of the two

tube connectors).

1

2

3

4

2

INSTALLATION…

Notes.

• Use tube of inert material, e.g., p.v.c.

• The sample inlet tube must incorporate a shut-off valve

at its up-stream end.

• Ensure the drain outlet tube is short, has a free fall and

is vented to atmosphere as soon as possible.

Fig. 2.2 External Pipe Connections

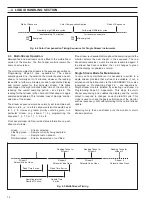

Information. To gain access to the constant head

assembly follow steps 1, 2, 4 and 5 in Fig. 1.1.

Note.

• One constant head assembly is fitted for each sample

inlet in multi-stream versions of the monitor.

• Fig. 2.2B shows six sample inlets and six

corresponding constant head assemblies.

2.5

Sample Connections – Fig. 2.2

Connect inlet and outlet tubes as shown in Fig. 2.2A (single

stream) and Fig. 2.2B (multi-stream).

Note. If the optional emergency sample facility has

been requested, a suitable 40 litre emergency sample

container must be provided by the user. A suggested

arrangement is shown in Fig. 4.2. Alternatively, a

constant, independent source may be used.