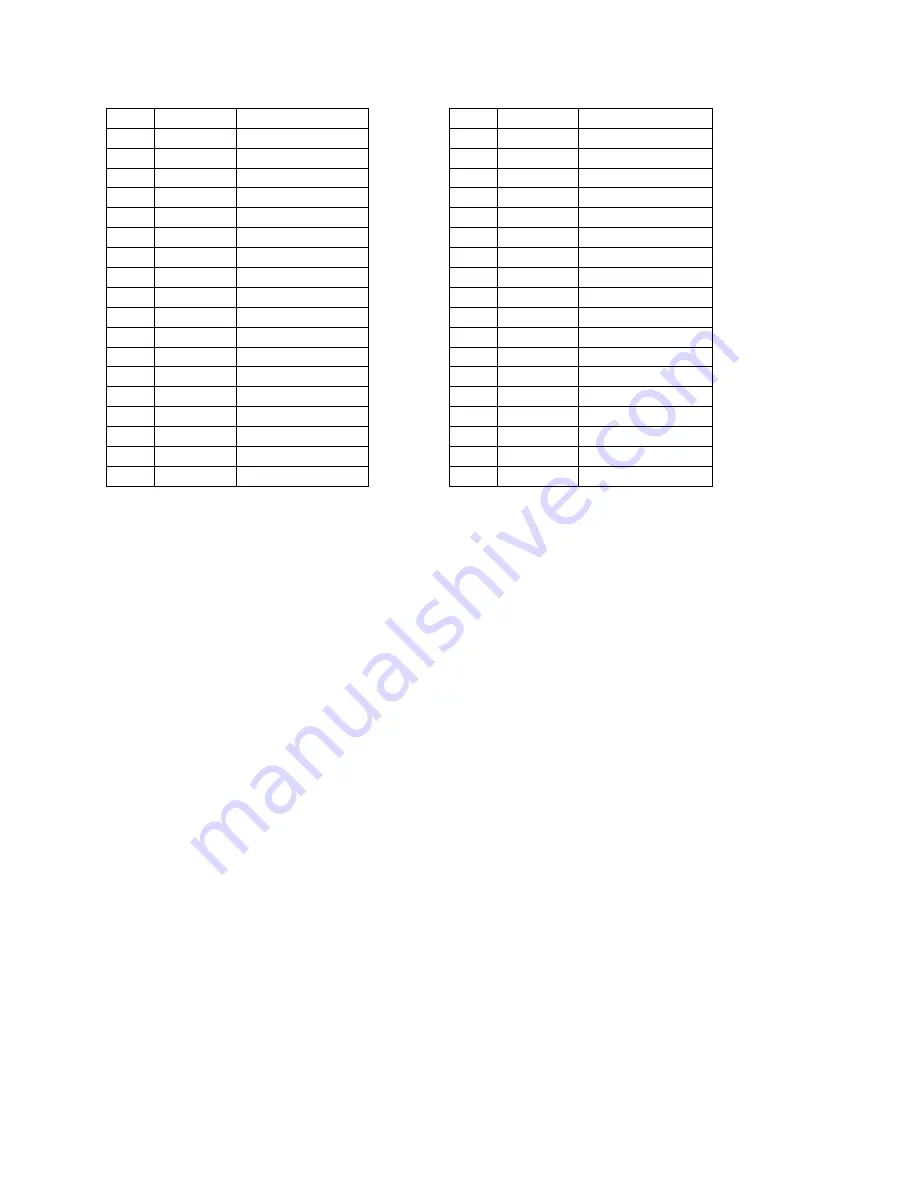

20

Item

Stock #

Description

Item

Stock #

Description

61

56206-061

Washer 6

79

56206-079

Bolt M8×50

62

56206-062

Washer

80

56206-080

Cylinder

63

56206-063

Oil seal 48.7×3.55G

81

56206-081

Ring58×52.5×4

64

56206-064

Nut M6

82

56206-082

Oil seal43.7×3.55G

65

56206-065

Front bracket

83

56206-083

Piston

66

56206-066

Upper pad

84

56206-084

stud

67

56206-067

Push rod

85

56206-085

stud

68

56206-068

Tine plate

86

56206-086

Spring

69

56206-069

Bolt M4×6

87

56206-087

Rear cover

70

56206-070

Down pad

88

56206-088

Oil seal 3.6×1.8G

71

56206-071

Nut M14

89

56206-089

Bleed screw

72

56206-072

Rubber plug

90

56206-090

Oil seal30×2.65G

73

56206-073

Work table guard

91

56206-091

Washer FC30×38×5

74

56206-074

Back bracket

92

56206-092

Dipstick

75

56206-075

Beam

93

56206-093

Oil seal 11.8×2.65G

76

56206-076

Step bolt M6×50

94

56206-094

Knob

77

56206-077

Work table guard

95

56206-095

Piston rod

78

56206-078

Rubber handle

96

56206-096

lock nut M14

Содержание AGT306

Страница 18: ...18 EXPLODED VIEW AND PARTS LIST...