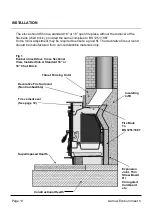

INSTALLATION

11

Aarrow Ecoburn Inset 5

FLUES AND CHIMNEYS

The flue draw is critical on any installation and

should be checked to ensure that it matches what

is specified. If it is higher than recommended,

provision must be made to correct the over draw.

The draw can vary in different weather conditions

and the customer should be made aware of this.

Failure to correct an over-drawing flue will

invalidate the warranty.

Please remember that chimney draught is

dependent on four main factors :

Flue gas temperature

Flue height

Flue size

Flue terminal

The stove must be connected to a suitable and

efficient flue that takes products of combustion

(fumes) from the stove outlet to the outside air. To

ensure a good up draught it is important that the

flue gases are kept warm and that the flue size

suits the stove. The termination of the outlet at the

top of the flue also needs to comply with Building

Regulations. The minimum effective height of the

flue must be at least 4.5 metres from the top of the

stove to the top of the flue outlet. When warm the

flue draught should be between 0.1 to 0.2 mb.

A chimney may comply with regulations but still be

subject to down draught and similar problems. A

chimney terminating above the ridge level is

generally less likely to suffer such problems.

If a new chimney is being provided it should fully

comply with the relevant Building Regulations that

specify the requirements for solid fuel burning

installations. Suitable types of chimney include the

following :

Masonry Chimney :

Built with clay or concrete

liners, or a chimney block system meeting Building

Regulations. These types of chimney should be

installed in accordance with the Building

Regulations and BS 6461:Part 1.

Factory Made Insulated Chimney :

Complying

with BS 4543:Part 2 (often called “Class 1

prefabricated metal chimney”). These types of

chimney should be installed in accordance with

Building Regulations and BS 7566: Parts 1 to 4.

Due to the gradual introduction of Europe Chimney

Standards, chimneys will be specified according to

their performance designation as defined in BS EN

1443 that covers the General Requirements for

chimneys. The minimum performance designation

required for use with solid fuel burning stoves is

T450 N2 S D3.

The flue and chimney installation must be carefully

checked by a competent person before fitting the

stove to ensure it is suitable and will work safely.

If the chimney is old (ie: built of brick or stone

without a liner) or being opened up for reuse

additional checks and smoke testing as described

in Appendix E of the Approved Document J 2002

Edition should also be carried out to ensure the

flue and chimney are in good operating condition.

Unless the existing flue is in good condition with

suitable access for collection and removal of

debris. If the flue size is more than 225mm (9”)

diameter or 200mm (8”) x 200mm (8”) square, a

suitable lining of 150mm (6”) diameter should be

fitted, or if the flue length is over 5.5 metres one

size larger than the appliance outlet should be fit-

ted. This should be a double skin stainless steel

flexible liner that is independently certified for use

with solid fuel. Details of suitable linings for use

with wood & solid fuel are given in the Official

HETAS guide that can be viewed on their website

at www.hetas.co.uk.

It is also important that suitable flue pipe complying

with the Building Regulations is used to connect

the stove to the flue in the chimney and that suit-

able access is provided into the flue for regular

inspection and sweeping of the flue ways.

The installer should comply with Building Regula-

tions requirements in respect of providing a Notice

Plate giving details on the chimney, flue lining,

hearth and fireplace installation. Approved Docu-

ment J of the Building Regulations for England &

Wales is available from The Stationery Bookshops

and can also be viewed at the ODPM website at

www.safety.odpm.gov.uk/bregs/brads.htm.

Details on the relevant Building Regulations and

BS British Standards are given in the “ General

Precautions” section of these instructions.

Chimneys should be as straight as possible.

Horizontal runs should be avoided.