Page 14

Aarrow Ecoburn Inset 5

INSTALLATION

FINAL CHECK LIST

Before handing over the installation to the

customer it is requirement under Document J that

the appliance is lit and the functioning of the

chimney system is checked for satisfactory

operation.

Be sure that the chimney is operating

and ALL smoke and fumes are vented to

the atmosphere through the chimney

terminal.

Check all joints and seals.

Clean the outside of the appliance to

prevent any stains becoming burnt on.

Check the flue draught which should

read 1 - 2mm, or 0.1 - 0.2 mbar.

If Building Control Consent route is being

sought please complete the check list on

page 15.

For a registered Competent Persons

Scheme, such as HETAS, please

complete the Certificate Of Compliance,

which is used for checking and reporting

the installation as imposed by the

Government

Explain the controls and operation of the

appliance to the customer.

The details on the

Building Control Consent

Checklist

( Page15 )

must

be checked and

completed in full by the installer at the time of

installation.

Please answer all questions as fully as possible.

Aarrow stoves

cannot be held responsible for the

chimney or installation.

MASONRY FIXING BOLTS

The Aarrow Ecoburn Inset 5 is supplied with masonry

fixing bolts to allow the installer to bolt the stove in

place, to the back of the chair brick if required.

In order to do this is will be necessary to remove the

„knock out‟ hole plugs in the rear of the stove.

These are located behind the tertiary air bar, which

must be removed to access these fastening holes.

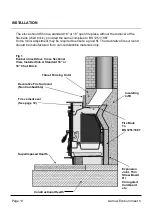

See Fig a, below.

Fig a.

Bolt fixing ‘knock outs’

The fixing bolts supplied with the stove are designed to

be screwed directly into masonry without the need for

any form of wall plugs. A pilot hole of 6mm will need to

be pre-drilled. Take care not to over tighten the fixing

bolts as this may damage the chair brick / wall, or strip

out the formed thread requiring involved repair work.

Fixing bolts supplied are M10 x 75mm, Longer bolts

may required if no chair brick is present these will have

to be supplied by the installer.

Installing without a chair brick in place

(See page 10 for diagram showing chair brick)

The stove is designed for installing into a fireplace with

a standard 16” or 18”chair brick in place. If the chair

brick has however been removed the stove can still be

installed but must be back filled with a 1:6 cement/

vermiculite mix. Anchoring the stove using masonry

bolts will require the use of longer bolts (not supplied)

capable of reaching solid masonry behind the infill mix,

as this will not provide a sufficiently strong fixing point.

The infill mix will need to be carefully dropped in behind

the stove by inserting one small hand full at a time

though the stove. This may take some time and must be

done very carefully to insure

NO VOIDS

are left behind

the stove body. Extra fire cement sealing where the

stove flue outlet lip meets back of the fireplace recess

may be needed. See fig b.

Fig b.

1:6 cement/

vermiculite infill

to fill void left by

removal of the

chair brick.

Carefully seal

here with fire

cement if

necessary

2 x 75mm fixing

bolts, supplied