18

ECM Driven Fan

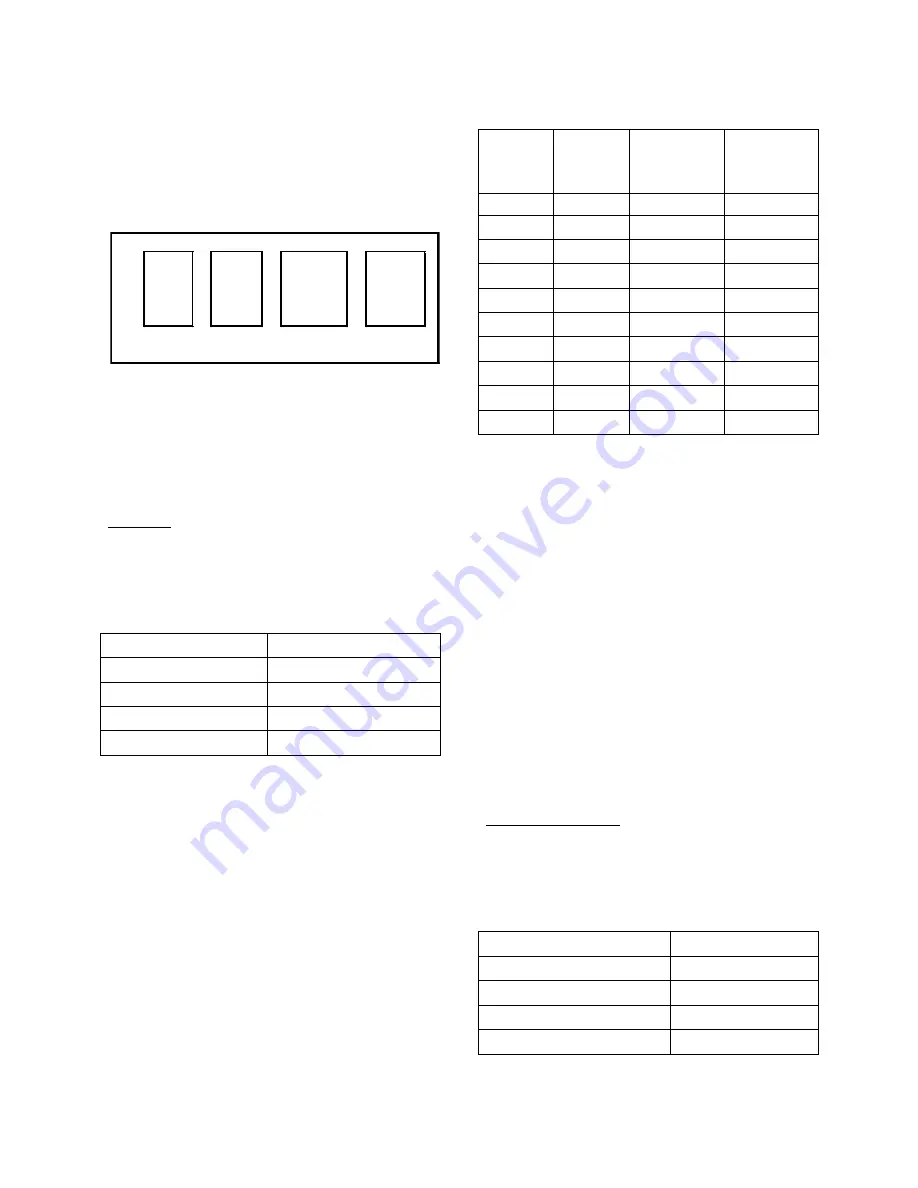

The Electrically Commutated Motor (ECM)

has selectable fan speeds as determined by

the configuration of four pins as shown in

FIGURE 2.

Figure 2 - Example Configuration of ECM

Fan Taps

Adjust the taps as desired for cooling,

dehumidification, and heating according to

the following instructions.

Cooling:

Units are preprogrammed from the factory

for a rated airflow rate of 400 cfm per ton as

shown in Table 3.

Table 3 - Factory Preset Air Flow

Model

Preset cfm

F1-060

2000

F1-048

1600

F1-036

1200

F1-024

800

* Maximum total static is 2.25” w.g.

The

high

speed for cooling may be selected

by setting the COOL and ADJUST fan

speed taps (shown in Figure 2). The setting

combinations are shown in Table 4.

Note: On the ADJUST tap, both of the ‘1’

selections have the same effect on motor

speed.

Table 4 - Cooling Fan Speed Tap Settings

F1-060/ F1-036/

COOL

Tap

ADJUST

Tap

F1-048

F1-024

(cfm)

(cfm)

2000

1200

A

1

2000

1200

D

1

1840

1150

B

+

1700

1020

A

-

1700

1020

D

-

1600

1000

B

1

1380

920

C

+

1360

850

B

-

1200

800

C

1

1020

680

C

-

A signal from the thermostat, showing a

need for dehumidification, will cause the

unit to slow the fan speed in order to allow

the air moving across the coil to get colder

thereby better dehumidifying the air. Fist

stage dehumidification has a low fan speed

of 67% of the selected max speed. Second

stage dehumidification has a fan speed of

45% of the selected max speed. NOTE: The

Modulating Hot Gas Reheat option must be

selected to have a second stage of

dehumidification.

In this comfort cooling application of the

ECM fan motor, heat and cool taps, A & D

have the same effect on motor speed.

Humidity Control:

Adjust the DELAY tap for humidity control

that is suitable for the climate according to

Table 5.

Table 5 - Climate Settings

CLIMATE

DELAY Tap

Humid

A

Sub-humid/Dry

B

Semi-Arid

C

Arid/Hyper-Arid

D

A

----

A

- -

1

- -

A

----

B

- -

B

- -

+

- -

B

- -

C

- -

C

- -

-

----

C

- -

D

- -

D

----

1

- -

D

- -

HEAT

COOL

ADJUST

DELAY

Содержание F1-060

Страница 31: ...31 ...

Страница 33: ...33 Figure 5 Modulating Hot Gas Reheat Piping Diagram with Air Handling Unit below Condensing Unit ...

Страница 36: ...36 Figure 8 Heat Pump Piping Diagram with Indoor Unit above Outdoor Unit ...

Страница 37: ...37 Figure 9 Heat Pump Piping Diagram with Outdoor Unit above Indoor Unit ...

Страница 38: ...38 Figure 10 Heat Pump Piping Diagram with Modulating Hot Gas Reheat and Indoor Unit above Outdoor Unit ...

Страница 39: ...39 Figure 11 Heat Pump Piping with Modulating Hot Gas Reheat and Outdoor Unit above Indoor Unit ...

Страница 40: ...40 Thermostat Installation and Wiring Figure 12 2 Stage Cooling with Electric Heat ...

Страница 41: ...41 Figure 13 2 Stage Cooling with Heat Pump and Electric Heat ...

Страница 42: ...42 Figure 14 2 Stage Cooling and Electric Heat with Hot Gas Reheat and Humidistat ...

Страница 43: ...43 Figure 15 Main Control Board for Units Equipped with Modulating Hot Gas Reheat ...

Страница 45: ...45 Figure 17 5kW Electric Heat ...

Страница 46: ...46 Figure 18 10 kW Electric Heat ...

Страница 47: ...47 Figure 19 15 kW Electric Heat ...

Страница 48: ...48 Figure 20 20 kW Electric Heat ...

Страница 49: ...49 Figure 21 25 kW Electric Heat ...

Страница 55: ...55 ...