holler

i-.4

I

I

S.

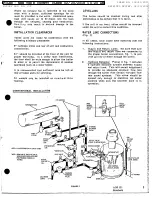

Water

8upply

Line

and

Operating

Pressures.

If

the

boiler

is

connected

to

heating

coils

These

boilera

can

be used

ONLY

In

a forced

exposed

to

refrigerated

air,

the

.boiler

piping

hot

water

heating

system.

The

water

supply

system

must

be

equipped

with

flow

valves

or

must

Include

a pressure

reducing

valve

other

automatic

means

to

prevent

gravity

to

establish

proper

system

operating

pree-

'

circulation

through

the

boiler

during

the

Modern,

fast

heating

hydronic

boilers

cooling

cycle.

function

best

with

a cold

fill

pressure

of

12

to

18

pol.

If

system

water

volume

and

op-

erating

temperature

can

be expected

to

create

7. ~

Circulating

Pump. .

A

circulating

pump

of

an

expanded

pressure

up

to

or

more

than

80

proper

capacity

must

be

selected

for

each

psI,

these

boilers

can

be

ordered

with

a 65

boiler

model

to

assure

adequate

water

flow

pal

pressure

relief.

Thla

will

be a aubstitute

for

each

boiler

firing

rate.

Refer

to

water

for

the

30

pal

valve.

normally

shipped

with

Information

on

page

3 for

pump

selection

and

the

boiler.

Relief

valve

relieving

pressure

install

as

shown

In fig.

1.~

should

not

exceed

the

operating

pressure

of

a

any

system

component.

The

A.

O.

Smith

Although

each

circulator

is

oiled

and

op-

.

boilers

are

rated

for

160

pal

maximum

work-

erated

by

the

manufacturer,

IT

MUST

BE

pressure.

OILED

AGAIN

BEFORE

OPERATED.

Oll

the

three

oil

cups

(2

on

the

motor,

1 on

the

Systems

with

large

water

volume

and

sys-

pump)

as

Instructed

on

the

oil

tube

supplied

tema

requiring

pressure

purging

should

be

with

the

unit,

fig.

8.

Installed

with

by-pass

piping

around

the

pressure

reducing

valve.

ha

-

4.

Vent

Valves.

It

Is

recommended

that

auto-

¬

. ,

matic,

loose

key

or :acrewdriver

type

vent

!

valves

be

Installed

at

each

convector

or

radiator

and

other

high

points

In

the

dis-

tribution

system.

If

automatic

vents

are

-*

,,

used,

pressure

at

all

times

must

be

high

enough

to

prevent

air

entry

through

these

devices.

5.

Manifold

Headers.

For

multi-loop

systems

using

one

circulator,

manifold

headers

must

_'-

be

installed

in

the

supply

and

return

lines.

;

.

For

2

or

3 circuits

using

S/4"

O.D.

copper

,

..

,

..,

tubing

and

2,

8 or 4 circuits

using

1/2"

O.D.

tubing,

the

manifold

should

be

at

least

1

1/2''

in

diameter.

The

circuits

should

be

spaced

on

the

header

at

a minimum

of

three

Inches

center

to

center.

install

a balancing

cock

in

each

return

line.

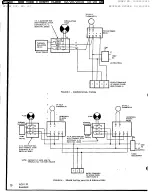

FIGuRI!

3

olLING

CIR CuL AToR

6.

Cooling

Piping.

Flow

control

valves,

manual

Thereafter,

during

the

heating-season,

lub-

or

motorized,

must

be.

Installed

to

control

>

ricate

the

three

oil

cups

at

least

once

every

water

flow

through

desired

unit,

fig.

2.

4 months.

Combination

heating-cooling

sys-

toma

should

be

lubricated

every

four

months

Water

temperature

In the

heating

syptem

must

year

around.

be

reduced

to

less

than

100

degrees

F

before

cooling

system

Is

started,

or

damage

to

the

chiller

unit

may

occur.

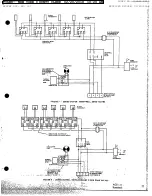

RETURN

EUPPLY

.

. _I.

BOILER

CHILLER

COOLiljG

CIRCUl.,ATOR

FIGuRa 2

REcDMaENDED

PIPING DIAGRAM

6

AOS

106

Roenbeck

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018