'

Use

2

or

3

teaspoonsful

in

bearing

oil

cup,

Use

Table

1 which

is

taken

from

Page

87

of

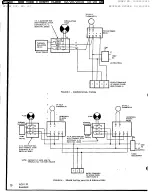

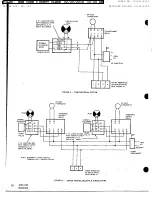

fig.

3,

and

10

or

12

drops

in

the

motor

oil

ANSI

booklet

Z223.1-1974

"NATIONAL

cups.

Use

no.

20 non-detergent

motor

oil.

FUEL

GAS

CODE"

and

is

based

on

a pres-

•

Follow

the

same

oiling

procedure

if

a

re-

sure

drop

of

0.3

inches

of water

and

a speci-

placement

circulator

is

installed

into

the

fic

gravity

of

0.60

(except

for

propane

gas

which

is

1.53).

If

the

service

pressure

is

system.

five

inches

water

column

or

less,

use

one

GAS

CONNECTl0NS

size

larger

pipe

than

specified.

Before

attaching

the

gas

line

to the

boiler,

be

sure

Where

it

is

necessary

to

use

more

than

the

that

all

gas

pipe

used

is

clean

on

the

inside.

average

number

of

pipe

fittings

in

gas

sup-

Contamination

in

the

gas

control

may

cause

it

to

ply

line,

use

a

larger

pipe

than

specified

to

leak

or fail

to

close

properly.

compensate

for

increased

pressure

drop.

Joint

compounds

(pipe

dope)

shall

be

applied

3.

Gas

Meter.

Be

sure

that

the

gas

meter

has

sparingly

and

only

to

the

male

threads

of

pipe

sufficient

capacity

to

supply

the

full

rated

joints,

Such

compounds

shall

be

resistant

to

the

gas

input

of the

boiler.as

well

as

the

require-

action

of

liquefied

petroleum

gases.

ments

of

all

other

gas

fired

equipment

sup-

plied

by the

meter.

If gas

meter

is

too

small,

Soap

and

water

solution,

or

other

material

ac-

ask

the

gas

company

to

install

a

larger

ceptable

for

the

purpose,

shall

be

used

in

locating

meter.

gas

leakage.

MATCHES,

CANDLES,

FLAME

OR

OTHER

SOURCES

OF

IGNITION

SHALL

NOT

BE

4.

Gas

Pressure

Regulators.

The

gas

pressure

USED

FOR

THIS

PURPOSE.

Gas

supply

pressure

pressure

regulator

is

included

in

the

combi-

to

the

control

of

this

boiler

must

not

exceed

1/2

nation

gas

valve

and

is

set

to

operate

on

the

psi

(14

inches

water

column)

pressure

in

order

to

boiler

rating

plate.

avoid

possible

leakage

or damage

to

the

control.

.

If

It

is

necessary

to

adjust

the

gas

pressure,

W

Threaded

unions

used

in

the

gas

lines

shall

be

remove

the

regulator

cap

on

underside

of

gas

•

of the

metabto-metal

type.

valve

and

turn

the

adjusting

screw

counter-

To

trap

any

dirt

or

foreign

material

In

the

main

clockwise

to

decrease

the

pressure.

Turn

gas

line,

a

dirt

leg

must

be

incorporated

in

the

the

adjusting

screw

clockwise

to

increase

bottom

of

a

convenient

pipe

rise,

see

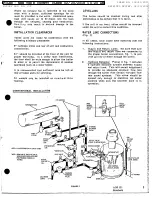

fig.

1.

the

pressure.

Do

not

exceed

the

pressure

Refer

to

ANSI

booklet

Z223.1-1974.

specified

as

over-firing

or

subsequent

dam-

age

to

the

batter

will

result.

(See

Table

2

In

all

cases,

local

codes

have

authority

over

the

for

correct

manifold

pressures

for

each

unit.)

following

instructions.

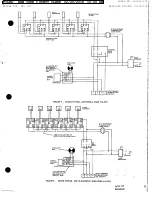

TABLE

2 - CORRECT MANIFOLD

PRESSURE FOR FULL

Ie

1.

Correct

Gas.

Make

sure

the

gas

on which

the

BOILER

INPUT

..

boiler

will

operate

is

the

same

as

that

speci-

fled

on

the

boiler

rating

plate.

Do

not

install

Madel Number

A.G.A. Rated Input

Natural Gas

*L.P.

Gases

the

boiler

if

equipped

for

a different

type

gas

NW-160

,

160,000

3.5

10.5

-

consult

your

supplier.

Hw-200

199,000

3.S

10.5

HW-225

225,000

3.5

2.

Sizing

Gas

Supply

Line.

If

local

codes

re-

quire

that

the

main

manual

gas

shutoff

valve

*Not listed for use with

L.P. - air gas.

y3s

be

Installed

outside

the

unit

at

a specified

height,

install

valve

as shown

in fig.

1.

.

VENT

CONNECTIONS

TABLE

1 - GAS SUPPLY PIPE SlZES (IN INCHES)

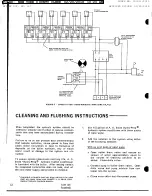

Remove

all

soot

or

other

obstructions

from

chim-

Distance

'

Natural Gas

L.P. Gas

ney

which

will

retard

free

draft.

To Boiler

From Meter

HW-160

HW-200

HW-225

HW-160

HW-200

1.

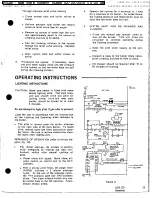

Flue

Pipe.

Size

and

install

the

flue

pipe

as

necessary.

10

3/4

3/4

3/4

1/2

1/2

4

•

30

1

1

1

3/4

3/4

The

connection

from

the

boiler

to

the

chim-

50

1

1

11/4

3/4

1

ney

should

be

run

full

size

and

should

have

80

1

1 1/4

1 1/4

1

1

a

minimum

pitch

upward

to

the

chimney

of

100

1 1/4

1 1/4

1 1/4

1

1

one

quarter

Inch

per foot

length.

Do

not

in-

150

1 1/4

1 1/4

1 1/4

1

1 1/4

stall

without

draft

diverter

and-do

not

Install

200

1 1/4

1 1/4

1 1/4

1

1 1/4

any

damper

in the

flue.

Be

sure

that

the

flue

pipe

does

not

extend

beyond

the

inside

wall

of

the

chimney.

AOS

123

'j

"

Roenbeck

FILED: NEW YORK COUNTY CLERK 02/20/2018 10:20 AM

INDEX NO. 190311/2015

NYSCEF DOC. NO. 337

RECEIVED NYSCEF: 02/20/2018