39

CAUTION

DO NOT USE A NYLON BRUSH OR OTHER STATIC CREATING

MATERIAL TO CLEAN DUST AND CARBON DEPOSITS FROM

HEATING SURFACES AND VENT.

SUCH DEPOSITS ARE FLAMMABLE AND MAY BE IGNITED BY

STATIC ELECTRICITY. USE A METAL BRUSH TO MINIMIZE THE

DANGER OF EXPLOSION

1.

Turn off the electrical power, main manual gas shutoff and

pilot valves.

•

Allow boiler parts to cool before disassembly.

2.

Remove the internal flue collector and vent pipe running to the

chimney.

•

Check parts and chimney for obstructions and clean as

necessary.

3.

Remove burners from boiler and other metal parts as required

to clean as necessary.

•

Refer to parts list supplied with this manual for disassembly

aid.

4.

Clean and reinstall the parts removed in steps 2 and 3.

•

Be sure the vent pipe has a minimum upward pitch of one

quarter inch per foot of length and is sealed as necessary.

5.

Restore electrical power and gas supply to boiler.

•

Check for gas leaks and proper boiler and vent operation.

HEAT EXCHANGER

PREVENTIVE MAINTENANCE

In most water supply systems some solids exist. As the water is

heated, these tend to drop out depositing as scale or lime. This

scale is relatively easy to remove before the unit becomes clogged.

WARNING

Lime accumulation can reduce the life of the equipment, reduce

efficiency and waste fuel. Boiler failure due to lime or scale build-

up voids the warranty.

See section on CIRCULATING PUMP to ensure you have selected

the proper size pump for your situation.

DELIMING

The amount of calcium carbonate (lime) released from water is in

direct proportion to water temperature and usage. The higher the

water temperature or water usage, the more lime deposits are

dropped out of the water. This is the lime scale which forms in

pipes, boilers and on cooking utensils.

The usage of water softening equipment greatly reduces the

hardness of water. However, this equipment does not always

remove all of the hardness (lime). For this reason it is recommended

that a regular schedule for deliming be maintained.

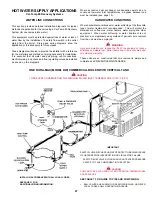

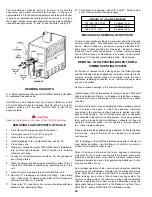

Figure 29 shows typical piping arrangement for gravity deliming of

lime deposits. For systems using recirculating deliming pumps

contact your A. O. Smith distributor.

Lime build-up may be seen when viewing the interior of the inlet/

outlet manifold through the pressure relief valve tapping.

GENERAL MAINTENANCE

These boilers are designed to give many years of efficient and

satisfactory service when properly operated and maintained. To

assure continued good performance, the following

recommendations are made.

The area around the unit should be kept clean and free from lint

and debris. Sweeping the floor around the boiler should be done

carefully. This will reduce the dust and dirt which may enter the

burner and pilot air passages, causing improper combustion and

sooting.

THE FLOW OF COMBUSTION AND VENTILATION AIR TO THE

BOILER MUST NOT BE OBSTRUCTED.

THE BOILER AREA MUST BE KEPT CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

Any safety devices including low water cutoffs used in conjunction

with this boiler should receive periodic (every six months)

inspection to assure proper operation. A low water cutoff device

of the float type should be flushed every six months. All relief

valves should be inspected and manually operated at least twice

a year. More frequent inspections may be necessary depending

on water conditions.

Periodic checks, at least twice a year, should be made for water

and/or gas leaks.

More frequent inspections may be necessary depending on water

conditions.

The boiler mounted gas and electrical controls have been designed

to give both dependable service and long life. However,

malfunction can occur, as with any piece of equipment. It is

therefore recommended that all components be checked

periodically by a qualified serviceman for proper operation.

RELIEF VALVE

The safety relief valve should be opened at least twice a year to

check its working condition. This will aid in assuring proper

pressure relief protection. Lift the lever at the top of the valve

several times until the valve seats properly and operate freely.

DANGER

THE WATER PASSING OUT OF THE VALVE DURING CHECKING

OPERATION MAY BE EXTREMELY HOT. BEFORE OPERATING

RELIEF VALVE MAKE SURE DRAIN LINE IS INSTALLED TO

DIRECT DISCHARGE TO A SAFE LOCATION SUCH AS AN OPEN

DRAIN, TO AVOID SCALDING OR WATER DAMAGE.

WARNING

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL

TO SHUT OFF, TURN OFF THE MANUAL GAS CONTROL VALVE

TO THE APPLIANCE.

VENTING MAINTENANCE

Qualified servicers should follow this procedure when the boiler’s

external heating surfaces and vent pipe need cleaning.