12

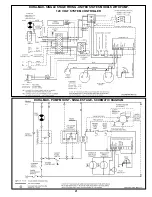

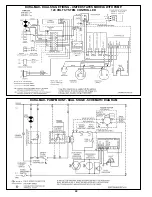

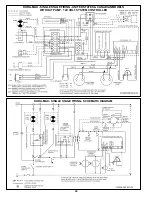

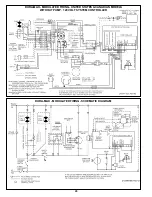

IF ANY OF THE ORIGINAL WIRE, AS SUPPLIED WITH THE

APPLIANCE, MUST BE REPLACED, IT MUST BE REPLACED

WITH TYPE 105°C WIRE OR ITS EQUIVALENT, EXCEPT FOR

THE FLAME SENSOR AND IGNITION CABLE WHICH ARE 250°C.

SERVICING WIRING AND/OR CONTROL

CAUTION

Label all wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation.

Verify proper operation after servicing.

SYSTEMS EQUIPMENT

INSTALLATION

The following is a brief description of the equipment required for

installations noted in this manual. All installations must comply

with local codes.

The boilers described in this manual may be used for space heating

or for the heating of potable water. If the heater is to be used for

hydronic space heating, follow the descriptions given for equipment

required for installation on pages 12 through 31. However, if units

are to be used for heating potable water, the information describing

specific systems is found starting on page 32. Installations must

comply with all local codes.

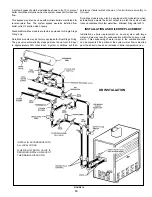

WATER SUPPLY LINE

These boilers can be used ONLY in a forced circulation hot water

heating system. Since most forced circulation systems will be of

the closed type, install the water supply line as shown on piping

diagrams, fig’s. 10 and 14.

Fast filling of large pipe, old radiator installations (where high

pressures are not available) requires bypassing of the pressure

reducing valve. Generally, pressure purging is not possible with a

well pump system. High point air venting is essential. For details,

refer to OPERATING INSTRUCTIONS section of this manual.

If the system is of the open type, a pressure reducing valve will not

be required as the water supply to the system will be controlled by

a manually operated valve. An overhead surge tank is required. A

MINIMUM PRESSURE OF 15 PSI MUST BE MAINTAINED ON

THE BOILER AT ALL TIMES to ensure avoidance of potential

damage to the boiler which may not be covered by the warranty.

EXPANSION TANK

If the system is of the closed type, install an expansion tank as

shown in fig. 10. The sizing of the expansion tank for a closed

system is very important and is directly related to the total water

volume of the system. Refer to ASME or other reliable specifications

for sizing.

An air separator as shown in the piping diagrams is recom- mended

especially for modern commercial hydronic systems.

VENT VALVES

It is recommended that automatic, loose key or screwdriver type

vent valves be installed at each convector or radiator.

SYSTEM HEADERS

Split systems with individual supply and return lines from the boiler

room should normally have this piping connected to supply and

return manifold headers near the boiler. To achieve good water

distribution with minimum pressure drop for several circuits,

manifolds should be larger than system loops.

The circuits should be spaced on the header at a minimum of 3"

(76 mm) center to center. Install a balancing cock in each return line.

Manifold headers are recommended for split systems with or without

zone valves and also those installations with zone circulators. If

the system is to be split at remote points, good practice requires

special attention be given to main pipe sizing to allow balancing of

water flow.

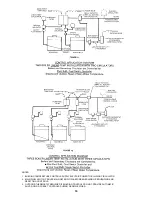

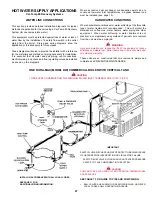

COOLING PIPING

The boiler, when used in connection with a refrigeration system,

must be installed so the chilled medium is piped in parallel with the

boiler with appropriate valves to prevent the chilled medium from

entering the boiler. See figure 7.

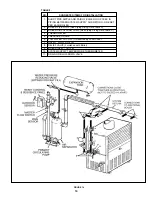

FIGURE 7

Water temperature in the heating system must be reduced to less

than 100°F before cooling system is started, or damage to the

chiller unit may occur.

The boiler piping system of a hot water boiler connected to heating

coils located in air handling units where they may be exposed to

refrigerated air circulation must be equipped with flow control valves

or other automatic means to prevent gravity circulation of the boiler

water during the cooling cycle.

Primary/secondary pumping of both the chiller(s) and the boiler(s)

is an excellent winter-summer change-over method, because

cooling flow rates are much more than heating flow rates. In this

way each system (heating or cooling) is circulated independently.

SAFETY FLOW SWITCH

The safety flow switch is a safety device which must be installed at

the water outlet of the unit to prevent main burner operation in the

event of inadequate water flow through the boiler.

This switch may be mounted in a horizontal pipe line or a vertical

pipe line with upward water flow. Do not install the switch where

the water flow is downward.

For best performance mount the switch in a section of pipe where

there is a straight run of at least 5 pipe diameters on each side of

the flow switch (i.e. do not locate adjacent to valves, elbows, orifices,

etc.).