53

53

53

53

53

PROTECTOR SWITCH

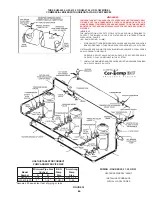

FIGURE 48

PRESSURE REDUCING VALVE

The screen in the pressure reducing valve may require occasional

cleaning due to foreign material in the water supply. This will

restrict the flow and could reduce the effectiveness of purging and

prolong filling time. To inspect the screen, close the main water

supply valve ahead of the pressure reducing valve and remove the

screen for cleaning, see fig’s. 1 and 2.

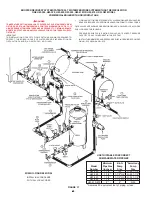

SAFETY FLOW SWITCH

The safety flow switch is a safety device which must be installed at

the water outlet of the unit to prevent main burner operation in the

event of inadequate water flow through the unit, see fig’s. 10 through

12 and 17 through 27.

An accessory package A. O. Smith No. 211480 containing a safety

flow switch is available for this application.

This switch may be mounted in a horizontal pipe line or a vertical

pipe line with upward water flow. Do not install the switch where

the water flow is downward.

For proper performance mount the switch in a section of pipe

where there is a straight run of at least 5 pipe diameters on each

side of the flow switch (i.e. do not locate adjacent to valves, elbows,

orifices, etc.).

The flow switch shall be mounted in a standard 1-1/2" x 1-1/2" x 1"

tee for a 1-1/2" pipe application. For larger pipe sizes use a

reducing tee in order to keep the switch as close to the pipe as

possible. Install the flow switch in the branch (top) opening of the

reducing tee and provide adequate paddle length in the flow stream.

For example in a 2" pipe installation use a 2" x 2" x 1" reducing tee.

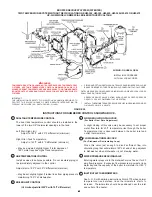

For 2", or 3" pipe use paddle segments as supplied. For other

pipe sizes (i.e. 1-1/4", 1-1/2" and 2-1/2") trim the paddle to the

proper pipe size, see fig. 49. If a standard tee is used, install a face

or hex bushing in the top opening. The paddle must be adjusted

or trimmed to the size of the pipe in which it will be installed.

CAUTION

Any part of the paddle must not touch the pipe or any restrictions in

the pipe. Screw the flow switch in position so the flat of the paddle

is at right angles to the flow. The arrow on the side case must point

in the direction of the flow.

TABLE 11 - SAFETY FLOW SWITCH

Minimum Pipe Rate

Contacts Closed Contacts Open

Model

(Flow)

(No Flow)

Number

GPM

LPS

GPM

LPS

HWB/HW-300

5.8

0.36

3.7

0.23

HWB/HW-399

7.5

0.47

5.0

0.31

HWB/HW-420

7.5

0.47

5.0

0.31

HWB/HW-520

13.7

0.86

9.5

0.60

HWB/HW-610/670

13.7

0.86

9.5

0.60

The safety flow switch may be field adjusted to obtain higher

minimum flow rates than those shown in table 11.

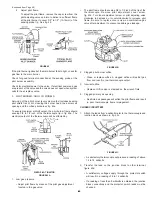

CAUTION

Paddle must be trimmed at the dotted arc. It must not touch

the pipe or have any restriction when installed

FIGURE 49

Содержание Burkay HW-300

Страница 27: ...27 27 27 27 27 FIGURE 21 SCHEMATIC CANADIAN MODELS JUNCTION BOX W 6 TERMINALS...

Страница 63: ...63 63 63 63 63...