3DPlatform.com

17

Operating the 3DP Workbench

Loading Filament

The filament spool holder is located on the back side

of the printer. Guide the filament through the filament

sensor and into the extruder.

Press and hold the button on the extruder to release

the hob while pressing firmly to insert the filament.

Tips for easy filament loading:

1. By hand, straighten the filament (remove the

natural curve from the spool).

2. Cut the end of the filament at an angle to assist

in the alignment within the extruder.

Hold the filament firmly and exert pressure until it begins

to extrude from the bottom of the nozzle. Make sure the

extruder is heated prior to loading or changing filament.

Filament Sensors

The 3DP Workbench is equipped with dual filament

sensors. This feature provides security during long prints.

When the filament runs out, the sensors put the printer

into Change Filament mode. The X axis and Y axis are

moved to the Home position and any remaining filament

is reversed out of the nozzle. An alarm sounds until the

filament is replaced and the center button on the LCD

Control Unit is pressed to resume the print.

For safety, if the printer is in Change Filament mode for

more than 30 minutes, the extruder will cool off.

Once the filament is replaced and the center button on

the LCD Control Unit is pressed to resume the print, the

X and Y axis will move into position but the printer will

pause until the extruder(s) reach the set temperature.

Once the set temperature is reached, the print will

resume.

Changing Filament

Filament can be changed at any time—when the printer is

idle (not printing) or mid-print.

• The extruder must be heated to 180ºC (minimum)

to remove or add filament.

• When printer is idle: raise the Z axis so the nozzle

is away from the glass. Press and hold the button

on the extruder to release the hob while manually

pulling out existing filament, then follow the

Loading Filament instructions.

• When the printer is mid-print: press the main

button on the LCD Control Unit, select Tune,

select Change Filament. This manually puts the

printer into Change Filament mode. Then follow

the Loading Filament instructions.

• When the printer is in Change Filament mode,

an alarm sounds until the filament is replaced

and the center button on the LCD Control Unit is

pressed to resume the print.

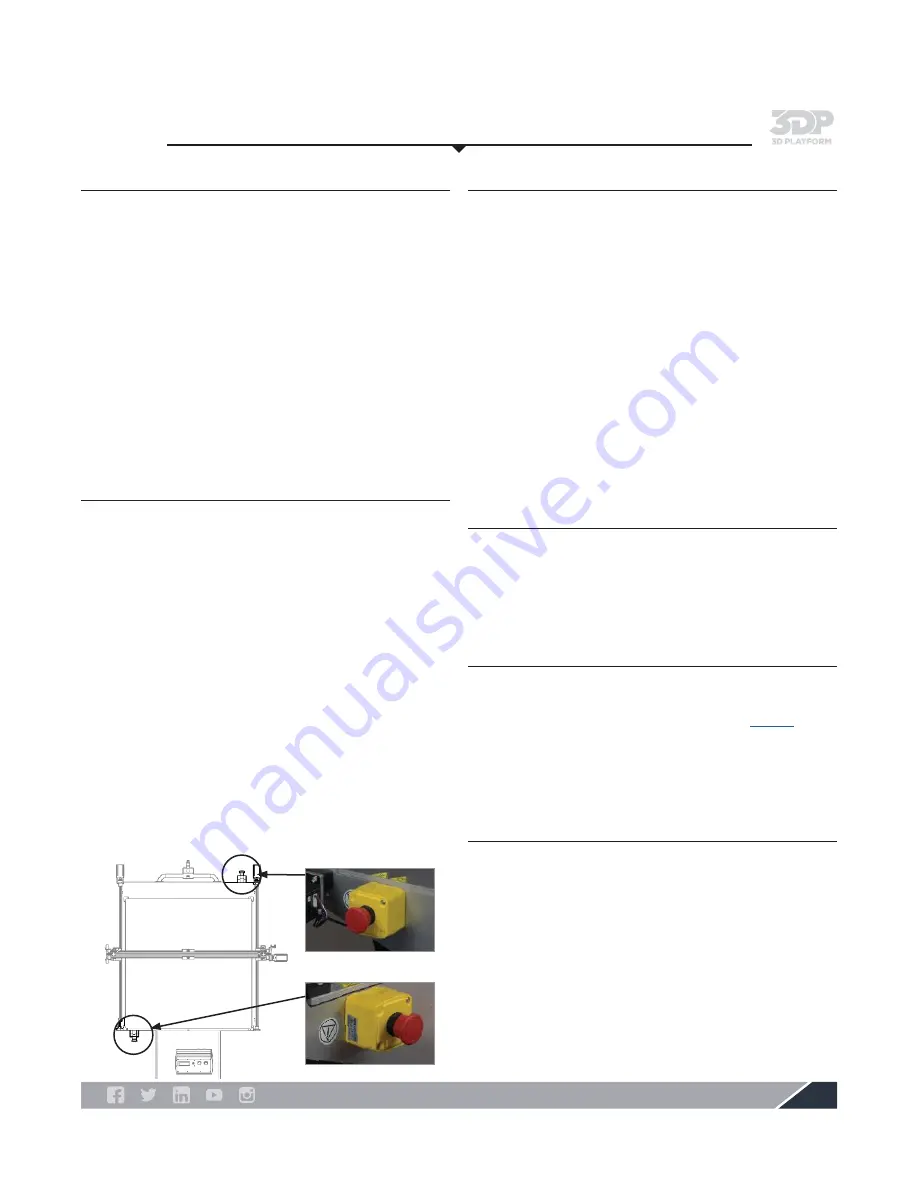

Emergency Stop (E-Stop) Function

There are two emergency stop buttons on the 3DP

Workbench. One located on the front and one located on

the rear of the machine.

When pressed inward, the E-Stop will immediately stop

movement of the actuators.

Caution!

Pressing the E-Stop does not remove power

from the machine.

Once an E-Stop is re-engaged—in the pulled out

position—the green power button on the control unit must

be pressed in order to resume function and use ability of

the printer.

Printing via USB Connection with Computer

The 3DP Workbench can be operated through the 3D

printing software's Manual or Machine Control Panel.

Follow the Connect the USB instructions on

page 8

. Once

connected, the printer can be operated via the computer

and software interface.

Printing via SD Card

The 3DP Workbench can be operated independently with

the LCD Control Unit and an SD Card. Select Print from

SD on the LCD Control Unit, then choose the .gcode file

you wish to print.

Front

Back