| 3 - INSTALLING CT28 ON THE WALL BRACKET

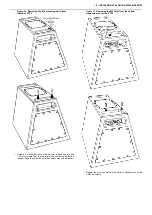

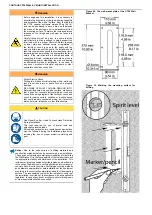

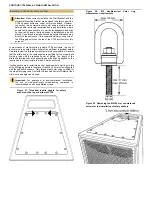

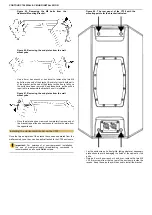

Figure 44. Tightening the bottom pan-lock bolt.

•

Using a 3 mm hex wrench, firmly tighten the pan-lock bolt into

the rotating bracket so that it cannot move laterally within the

wall-mounted yoke.

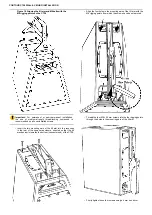

Figure 45. Inserting the upper pan-lock bolt – 0°

(perpendicular) pan angle shown.

•

Insert and thread the other M4 ×16 mm pan-lock bolt into the

bracket through the appropriate hole in the upper end-plate of

the wall-mounted yoke.

Figure 46. Tightening the upper pan-lock bolt.

•

Again, using a 3 mm hex wrench, firmly tighten the pan-lock bolt

into the rotating bracket so that it cannot move laterally within

the wall-mounted yoke.

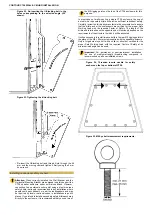

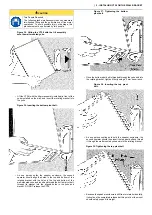

Attaching a safety bridle

If the CT28 speaker enclosure has been equipped with eye bolts for a

redundant safety bridle (steel wire rope), these must be attached to the

external anchor before concluding the installation.

ATTENTION

A redundant safety must be anchored to a point higher than the

enclosure and, where possible, to a separate structural member than

the Bracket. If the secondary safety bridle must be anchored using

a fastener to the same structural member as the Bracket, its anchor

must be installed at least one speaker-length away from the anchors

holding the Bracket. Use only steel wire ropes or steel chains that

conform to applicable regulations or norms in terms of construction

and Working Load Limit. These must be of proper length and installed

in such a position as to prevent the enclosure from falling more than

20 cm in the case of failure of the Bracket or the structure to which

it is installed.

In most cases of wall mounting a single CT28 enclosure, the use of a

two-leg safety bridle will provide sufficient redundant safety. The legs

of the bridle must be steel wire rope, with thimbles and each with a

Working Load Limit rated at least 2.5x the weight of the enclosure. The

legs can be permanently closed and swaged through the eye bolts, or

attached with rated shackles or locking carabiners. Carefully review third-

party manufacturers' documentation to assure that the bridle and all its

components are certified for the proper load limit with the required Safety

Factor. The length, material and termination on the sling that attaches

the bridle to the anchor point will obviously depend on the requirements

of the structure or point to which it will be anchored.

Figure 47. An example of a steel wire rope safety

bridle attached using moused shackles (rear view).

Содержание Contour CT28

Страница 1: ...Contour CT28 Wall Ceiling Installation...

Страница 50: ......