General Safety Information

Coalescing filters are utilized in a variety of

air system applications. Because the

coalescing filter and other components

(compressor, spray gun, filter, regulator,

hoses, etc.) make up a high pressure

pumping system, the following safety

precautions should be observed at all times.

1. Read the instruction manuals for each

component carefully before attempting to

assemble, disassemble, or operate your

particular system.

2. Do not exceed the pressure rating of any

component in the system.

3. Protect material lines and air lines from

damage or puncture.

4. Never point a spray gun at oneself or any

other person. Accidental discharge may

result in serious injury.

5. Check hoses for weak or worn condition

before each use, making certain that all

connections are secure.

6. Release all pressures within the system

before attempting to service any

component.

Water vapors will pass

through these units

and could condense into liquid form

downstream as air temperature drops.

Install an air dryer if water vapors could

have a detrimental effect on the

application.

Materials

Body: Zinc

Bowl: Polycarbonate

Element: Synthetic fiber and polyurethane

foam

Elastomers: Neoprene and nitrile

Installation

1. Shut OFF air pressure. Install filter in air

line vertically (bowl down), with air flow

in direction of arrow on body, upstream

of regulators, lubricators, and cycling

valves, as close as possible to the air supply

when used as a main line filter or as close

as possible to the device being serviced

when used as a final filter.

2. Connect piping to proper ports using pipe

thread sealant on male threads only. Do

not allow sealant to enter interior of unit.

3. Be sure bowl is turned fully clockwise into

body before pressurizing. Tighten hand tight.

4. Install a Speedaire air line filter with a 5

µm element upstream of the coalescing

filter to obtain maximum element service

life.

Operation (See Figure 2)

1. Depress manual drain to expel

accumulated liquids. Keep liquids below

element (Ref. No. 11).

2. Replace filter element when pressure

differential across element exceeds 10 psi.

An excessive pressure drop across a

saturated but uncontaminated element

may indicate operation above maximum

flow rate (CFM). See

Specifications

.

Disassembly (See Figure 2)

1. Filter can be disassembled without

removal from air line.

2. Shut OFF inlet pressure. Reduce pressure

in inlet and outlet lines to zero.

3. Remove bowl by turning

counterclockwise.

4. Disassemble in general accordance with

the item numbers on Figure 2. Do not

remove the drain (Ref. No. 3) unless

replacement is necessary. Remove and

replace only if drain malfunctions or

converting to automatic drain.

Cleaning (See Figure 2)

1. Clean polycarbonate bowl with warm

water only. Clean other parts with warm

water and soap.

2. Rinse and dry parts. Blow out internal

passages in body (Ref. No. 1) with clean,

dry compressed air.

3. Inspect parts. Replace those found to be

damaged. Replace plastic bowl with a

metal bowl if plastic bowl shows signs of

cracking or cloudiness.

Assembly (See Figure 2)

1. Lubricate o-rings and the lip of the auto

drain valve (Ref. No. 8) with o-ring grease.

2. Assemble filter as shown on Figure 2.

Torque Table

Ref. No.

Inch Pounds (N-m)

3 (manual drain)

1.5 to 2.5 (0.17 to 0.28)

5, 10 (bowl)

5 to 10 (0.56 to 1.13)

12 (Element)

5 to 10 (0.56 to 1.13)

Speedaire

®

Coalescing Filters

Refer to Form 5S6040 for General Safety Information and Warranty

Operating Instructions & Parts Manual

4ZL16, 4ZL17

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and

others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for

future reference.

Form 5S6074

®

E

N

G

L

I

S

H

E

S

P

A

Ñ

O

L

F

R

A

N

Ç

A

I

S

Printed in U.S.A.

06530

0708/244/VCPVP

Description

Speedaire coalescing filters remove oil aerosols and submicron solid particles down to 0.01

micron from air supply lines by means of a coalescing filter element. Typical applications

include air bearings, air conveying, high speed air motors, pneumatic instrumentation and

controls, gauging equipment, and spray painting. Units are equipped with a manual drain.

Depress manual drain valve to drain accumulated liquids.

4ZL16

150 psi

125°F

6 cfm

1/8"

Polycarbonate 0.01µm

0.28

4ZL17

150

125

6.5

1/4

Polycarbonate 0.01

0.28

* At 100 psi inlet pressure, saturated element, and 3 to 5 psi pressure drop.

Maximum

Element

Inlet

Maximum

Maximum

Micron

Weight

Model

Pressure

Temperature CFM *

Ports

Bowl

Rating

(lbs)

Specifications

1

.4

5

(3

7

)

1.63 (42)

6

.2

2

(1

5

8

)

*

0

.3

8

(1

0

)

4

.2

5

(1

0

8

)

* Minimum clearance required to remove bowl.

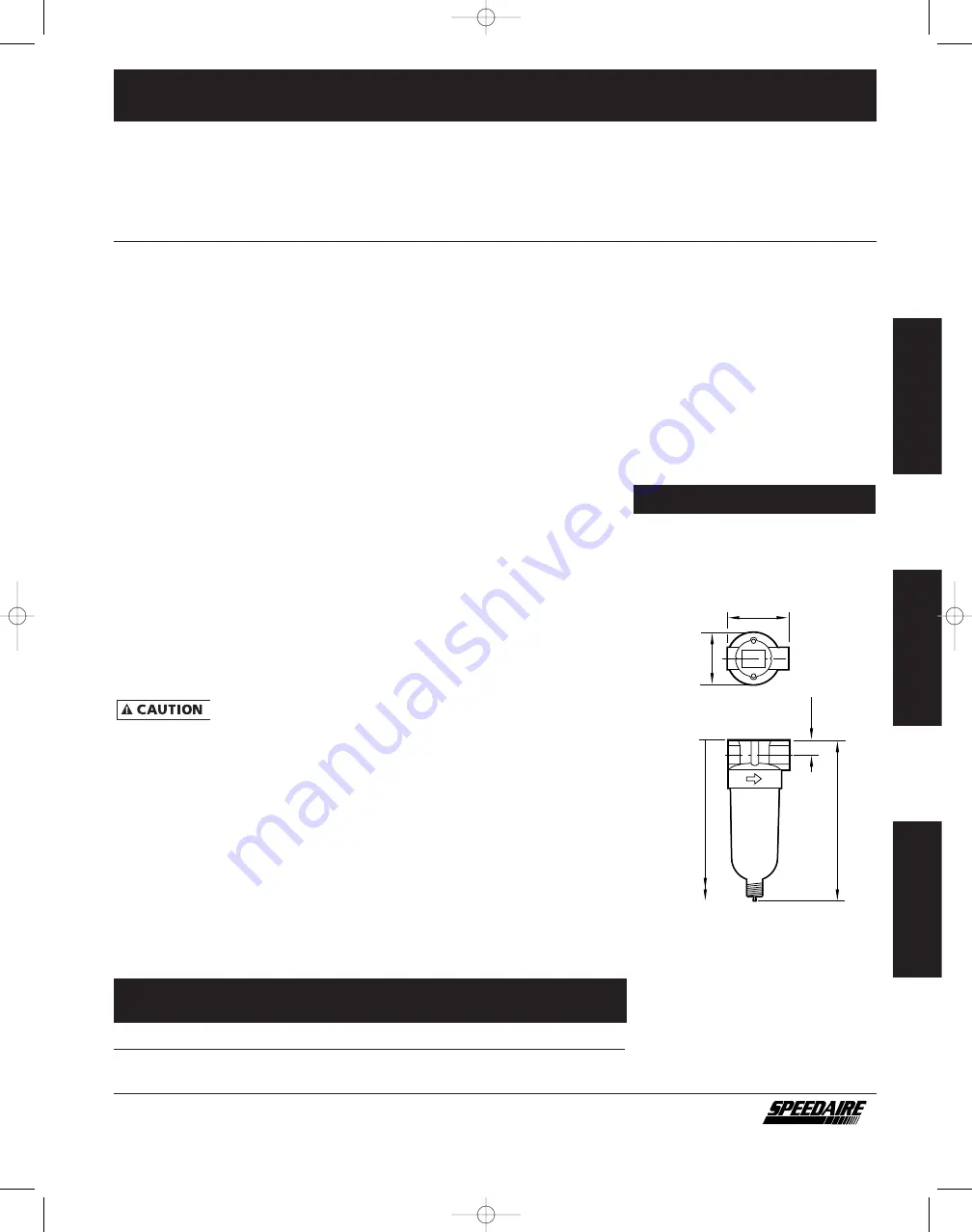

Figure 1 - Dimensions in inches (mm)

5S5317:5S4373

8/30/08 3:55 PM Page 1