HP J1530C Rack Kit for

rp74xx/rx76xx/SEU

Servers

Installation Instructions

Kit contents

WARNING:

Do not mount this rack integration

kit in a rack with sectional columns, such as the

HP 5642 rack.

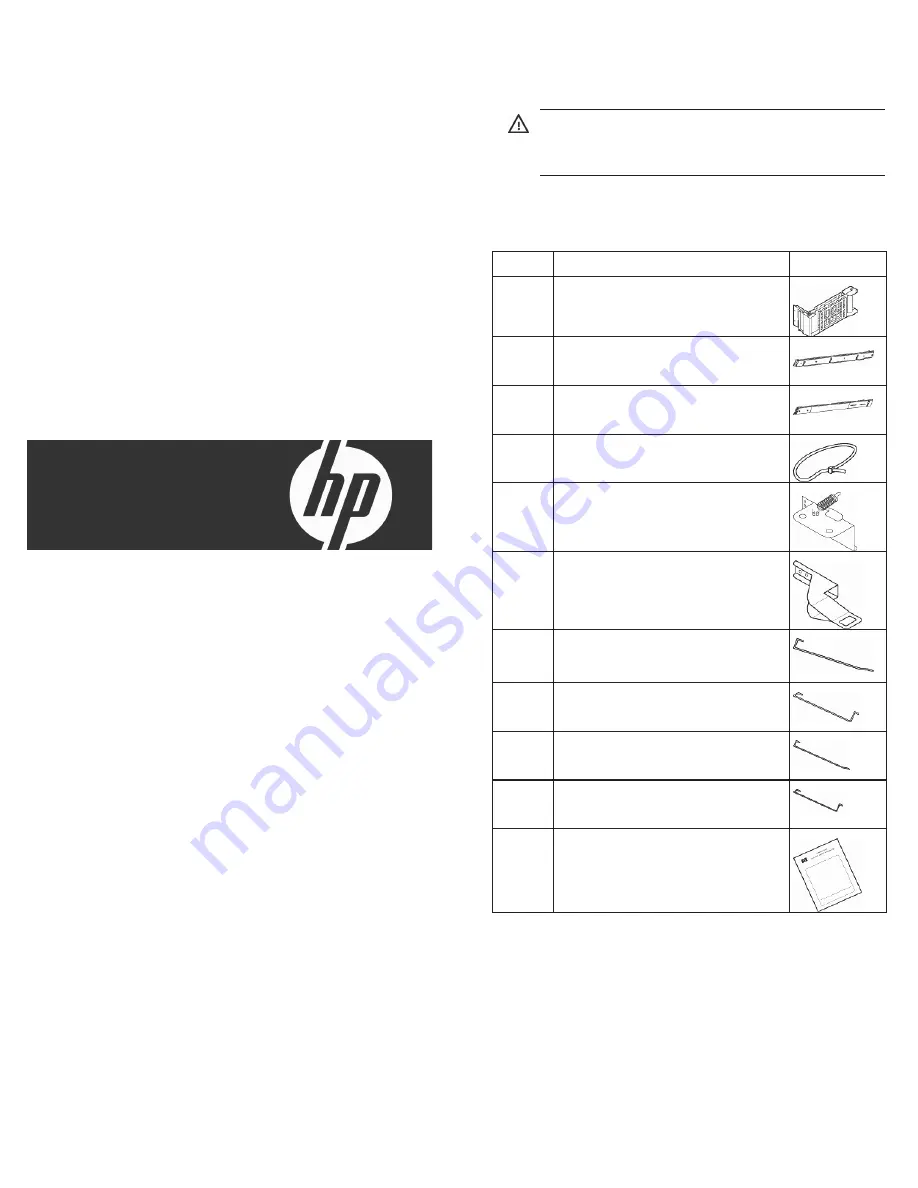

If any of the following items are missing or damaged, contact

your HP authorized reseller. The following hardware pieces

are included in this kit.

Quantity Description Picture

1

Cable management arm

(5069-6366)

1 Slide,

left

(A6434-04045)

1 Slide,

right

(A6434-04046)

3 Cable

tie

(1400-3011)

2

Mounting bracket and spring

(5069-6363)

2 Actuator

bracket

(5003-0540)

1 Long

rod,

17U

(5003-0538)

1 Short

rod,

17U

(5003-0541)

1 Long

rod,

10U

(5003-0539)

1 Short

rod,

10U

(5003-0542)

1 Installation

instructions

© Copyright 2005, 2007 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The

only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing

herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Part Number 391342-004

April 2007 (Fourth Edition)

Summary of Contents for J1530C

Page 5: ......