Reviews:

No comments

Related manuals for WH9DM

PDSS 310 A2

Brand: Parkside Pages: 71

XR DCF887

Brand: DeWalt Pages: 48

N863724

Brand: DeWalt Pages: 8

PRO TMP

Brand: topmaster Pages: 60

1003-097-317

Brand: Husky Pages: 33

CP7782 Series

Brand: Chicago Pneumatic Pages: 14

SX745-2

Brand: Sunex Tools Pages: 13

SX4360-6

Brand: Sunex Tools Pages: 13

354238-2010

Brand: Parkside Pages: 43

BTL061

Brand: Makita Pages: 36

BTW152

Brand: Makita Pages: 10

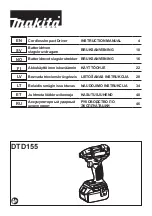

DTD155RME

Brand: Makita Pages: 52

DT03

Brand: Makita Pages: 28

TD112DZ

Brand: Makita Pages: 76

TD127D

Brand: Makita Pages: 12

0088381803212

Brand: Makita Pages: 76

0088381099172

Brand: Makita Pages: 40

0088381000840

Brand: Makita Pages: 36