3M

™

Mining Cable Splice Kit 3104

Instructions

Kit Contents:

1 Scotch

®

Heavy Duty Mining Tape 31, 2" x 8.5'

1 3M

™

Temflex

™

Vinyl Electrical Tape 1700P, 1½" x 44'

2 Scotch

®

Electrical Shielding Tape 24, 2" x 10'

1 3M

™

Cable Cleaning Preparation Kit CC-2-Dry

2 Scotch

®

Linerless Rubber Splicing Tape 130C, 1½" x 30'

1 Instruction Sheet

Note: Scotch

®

Linerless Rubber Splicing Tape 130C is applied highly-stretched with

tacky side DOWN.

Technical Information:

For use on 3-conductor mine and portable cables, type SHD-GC

#6 AWG–1/0 kcmil (14-50 mm

2

)

2 kV

Cables up to 500 kcmil (250 mm

2

) will require the use of additional tapes.

Mine Safety and Health Administration Acceptance:

P-07-KA080005/00-MSHA

DANGER

Before attempting any cable repairs, make sure that the proper cable is disconnected,

locked out and suitably tagged.

CAUTION

Working around energized systems may cause serious injury or death. Installation

should be performed by personnel familiar with good safety practice in handling

electrical equipment. De-energize and ground all electrical systems before installing

product.

August 2009

78-8127-6849-3-C

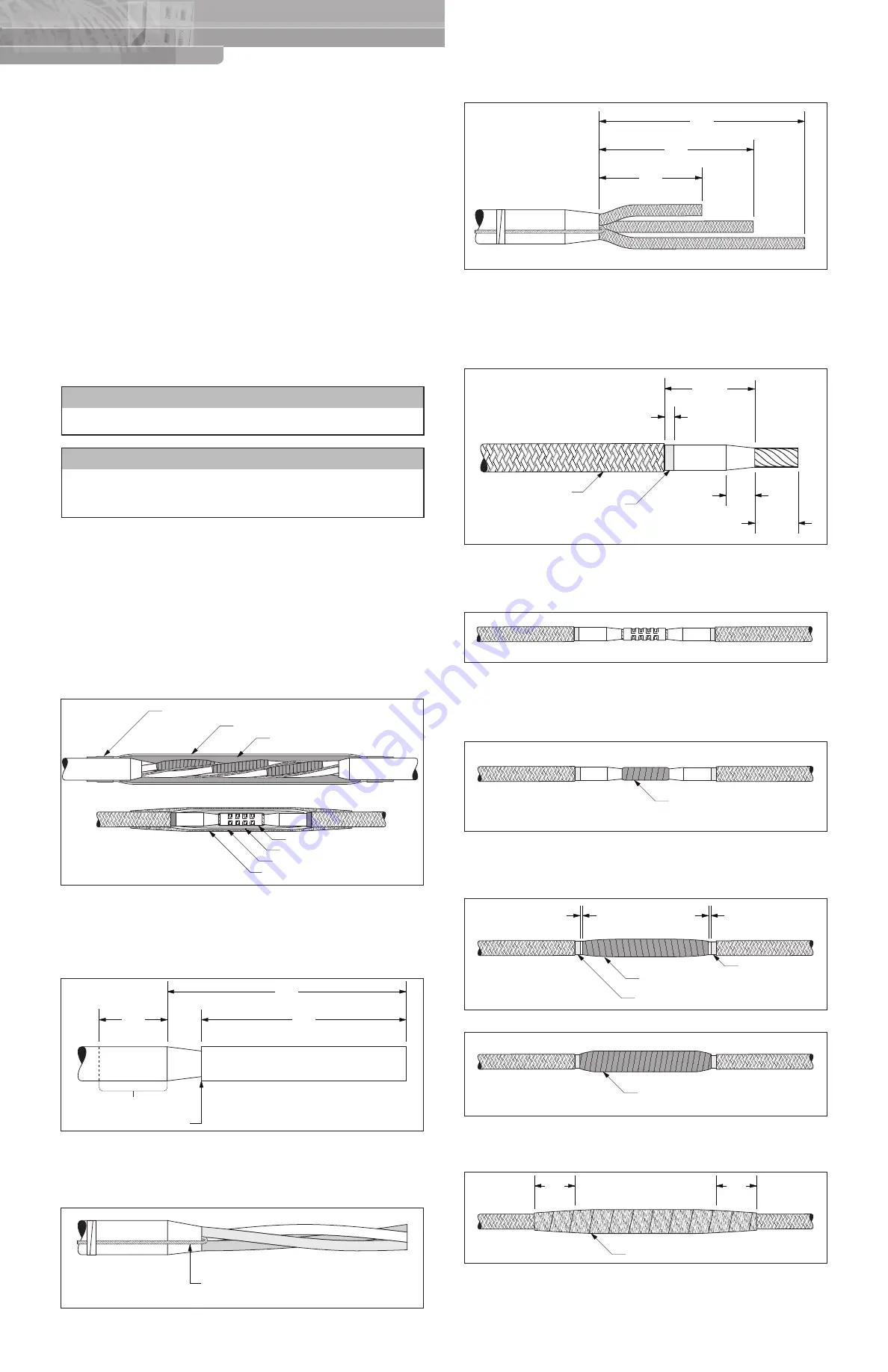

Scotch

®

Linerless Rubber Splicing Tape 130C

Scotch

®

Heavy Duty Mining Tape 31

3M

™

Temflex

™

Vinyl Electrical Tape 1700P

3M

™

Temflex

™

Electrical Vinyl Tape 1700P

Scotch

®

Linerless Rubber Splicing Tape 130C

3M

™

Temflex

™

Vinyl Electrical Tape 1700P

Scotch

®

Electrical Shielding Tape 24

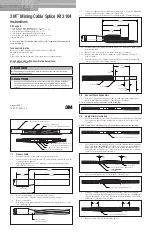

1.0 Prepare Cable

1.1

Position cable ends so that conductor color rotation matches.

1.2

Circle-cut cable jacket approximately 12" (305 mm) from each end. Be sure not

to damage cable conductors.

1.3

Measure approximately 14" (355 mm) from cable end and fully taper cable

jacket down to circle cut.

Circle cut cable jacket

12"

(305 mm)

14"

(355 mm)

Scuff & Clean

4"

(100 mm)

1.4

Remove approximately 12" (305 mm) of cable jacket.

1.5

Scuff and clean 4" (100 mm) of cable jacket beyond top of taper.

1.6

Remove cable fillers.

1.7

Fold back grounds and ground check conductors and temporarily tape to cable

jacket with vinyl tape.

Fold back grounds &

ground check conductors

1.8

Select one conductor and cut conductor approximately 9" (230 mm). Match this

conductor with same color conductor on opposite end.

1.9

Take next conductor in rotation and cut approximately 6" (150 mm) from end.

6"

(150 mm)

9"

(230 mm)

12"

(305 mm)

1.10

From the end of each conductor cutback remove 3½" (90 mm) of braid or tape

metallic shielding.

1.11

Remove cable color-coding to ¼" (6 mm) from edge of shielding.

1.12

Remove insulation from ends of conductors for one-half connector length

plus ¼" (6 mm).

1.13

Pencil insulation for ¾" (20 mm), sand smooth and even with electrical grade

abrasive cloth from cable cleaning materials.

3½"

(90 mm)

½ connector length

+ ¼" (6 mm)

Color-coding

Metallic shield

¾"

(20 mm)

¼"

(6 mm)

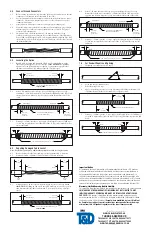

2.0 Connect Phase Conductors

2.1

Join power conductors with proper connectors and appropriate crimping tool.

Make certain conductors butt up to center indents of connector.

Note: Ground wires and ground check will be joined later.

3.0 Apply Primary Insulation

3.1

Apply one half-lapped layer of 3M

™

Temflex

™

Electrical Vinyl Tape 1700P from

edge of taper to edge of taper, making sure to completely cover edges of the

connector

NOTE: Scotch

®

Glass Cloth Tape 27, while not included, may be used at this time.

3M

™

Temflex

™

Electrical Vinyl Tape 1700P

3.2

Apply highly-stretched half-lapped layers of Scotch

®

Linerless Rubber Splicing

Tape 130C (

tacky side DOWN

) over 1700P tape and up onto tapers. Build up

half-lapped layers of tape gradually going out on existing insulation to 1/8" (3

mm) from edge of original color coding. Tape should be wrapped to a thickness

equal to or greater than original insulation.

Scotch

®

Linerless Rubber Splicing Tape 130C

Tacky Side DOWN

Color coding

Color coding

1/8"

3 mm

1/8"

3 mm

3.3

Apply one half-lapped layer of 1700P tape over the 130C tape.

3M

™

Temflex

™

Electrical Vinyl Tape 1700P

3.4

Starting 2" (50 mm) up on exposed metallic shielding, wrap one half-lapped

layer of Scotch

®

Electrical Shielding Tape 24 over the vinyl tape continuing onto

opposite shielding for 2" (50 mm). Wrap back down the shielding, secure with a

half hitch or square knot, and trim ends.

Scotch

®

Electrical Shielding Tape 24

2"

(50 mm)

2"

(50 mm)

3.5

Repeat sections 2.0 & 3.0 for remaining phases.