7 Operation and maintenance

ZIMM Actuator

2023

Version 0.6

32

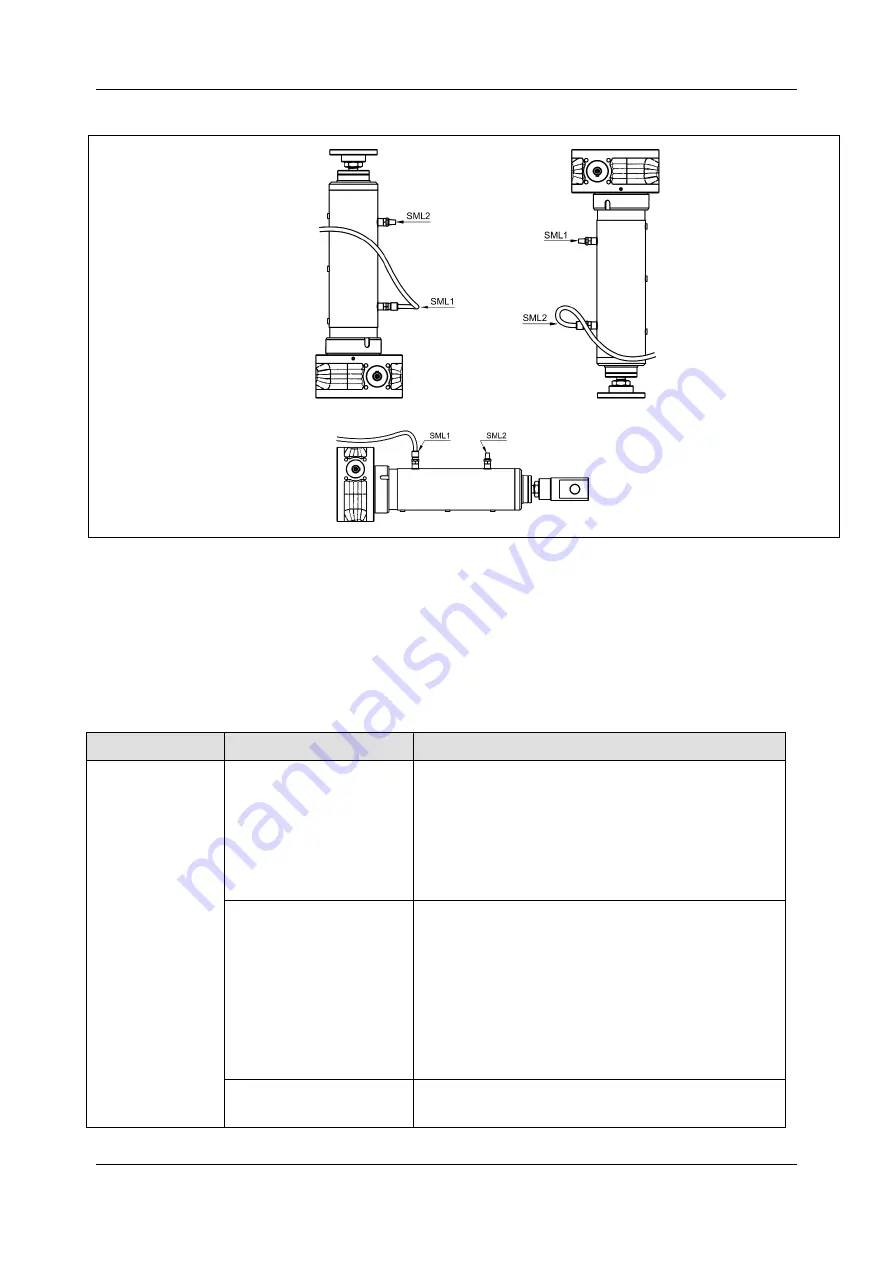

Fig. 13: Ventilation position with automatic lubrication

7.3

Troubleshooting

If faults are evident, these should be localised according to specific

criteria, and rectified by application of appropriate actions. The following

table offers start points as assistance for troubleshooting.

Fault

Possible cause

Action

Spindle is

squeaking or

vibrating

Wrong spindle grease,

stick-slip

Use different grease:

– with high viscosity base oil

– with additives

– possibly with solid lubricants

ZIMM will be happy to advise you.

Geometry error in the

system

Check alignment:

– Parallel positioning of the ZIMM Actuators

(thrust tubes, cylinder tubes) to each other

– Parallel positioning of the ZIMM Actuators to

the guides

– Angularity of the screw surfaces (gears, nuts,

flanges, etc.)

Unfavourable spindle

frequency

Change speed: slower or faster (observe limit

values)

Summary of Contents for ZA-25

Page 33: ......