OWNER’S MANUAL - 3 - YF-48N A/0

MACHINE DESCRIPTION

MIG350 CO

2

gas shielded welding machines of our company are inverter welding machines manufactured by our

company applying most advanced inversion technology in the world.

The development of welding equipment benefits from the appearance of the inverter power supply theory and

components. The principle is to commutate the power frequency of 50Hz/60Hz into direct current, and then utilize the

high-power device IGBT to invert it into high frequency (15K/16K), then reduce the voltage and commutate, and output

high-power D.C power supply via Pulse Width Modulation (PWM). Since the switch power inversion technology is adopted,

the weight and volume of the welding machine is brought down greatly with a conversion efficiency increase of more than

30%. Characteristic: stable wire feed rate, little splatter, portable, energy-saving, low electromagnetic noise.

The CO

2

gas shielded welding machine of our company is equipped with unique electronic reactor circuit, precisely

controlling the short-circuiting transfer and mixed transfer of welding, producing excellent welding characteristic.

Compared with silicon controlled welding machine and welder with taps, our products have the following merits: stable

wire feed rate, portable, energy-saving, electromagnetic noise free. Besides, our products have merits such as electric

network fluctuation self-compensation function, little splatter, good arc starting, deep welding pool, high duty cycle etc.

This equipment can be applicable in large-scale plants such as shipyards, steel structure plants etc. featuring high

efficiency and energy-saving.

The CO

2

gas shielded welding machine of our company has function of ending arc On/Off. Arc starting current and ending

arc current can be adjusted separately, being very applicable for automatic welding. This machine is most suitable for the

welding of mild steel, alloy steel and stainless steel.

Thank your for choosing our products. Please feel free to propose your valuable suggestions; we will make efforts to

perfect our products and service.

WARNING

!

The machine is mainly used in industry. It will produce radio wave, so the worker should make

fully preparation for protection.

Summary of Contents for MIG-350

Page 1: ......

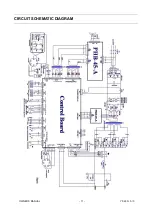

Page 12: ...OWNER S MANUAL 11 YF 48N A 0 CIRCUIT SCHEMATIC DIAGRAM...