OWNER’S MANUAL - 16 - YF-48N A/0

DAILY CHECKING

Position

Checking keys

Remarks

Pressing arm

If put the arm to the suitable indicating level

Lead to unstable arc and wire sending

Wire lead tube

If powder or residue store up in the mouth of the

tube

Clean the residue and check the reason

and solve it

Wire diameter and the tube inner diameter match

or not

If not match, lead to unstable arc and

residue

If the tube mouth center matches the wire wheel

slot center or not. (Eyeballing)

If unmatched, lead to unstable arc and

residue

Wire wheel

Wire diameter matches the wheel’s requirement

If the wheel slot blocked

1. Lead to unstable arc and residue, and

block wire tube

2. Change new one if necessary

Pressure

wheel

Check the stability of its move, and wearing-out

of pressed wire, the narrowing of its contact

surface

Lead to unstable arc and wire sending

Position

Checking keys

Remarks

Torch cable

1. If torch cable over bended

2. If the metal connecting point of mobile plug

loosen

1. Cause poor wire sending

2. Unstable arc if cable over bended

Output cable

1. Wearing-out of the cable insulated material

2. Cable connecting head naked (insulation

damage), or loosen (the end of power supply,

and cable of main material connecting point)

For life security and stable welding,

adopt

suitable

method

to

check

according to working place

Simple check daily

Careful and in-depth check on fixed

period

Input cable

1. If the connection between the plug and the

power socket is firm

2. If the power input end cable fixed

3. If the input cable is worn out and bares the

conductor

Earth cable

If the earth cable that connects the main part

is broken and connects tightly

CABLE

WIRE SENDING MACHINE

Summary of Contents for MIG-350

Page 1: ......

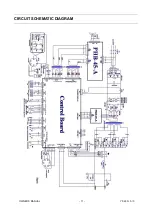

Page 12: ...OWNER S MANUAL 11 YF 48N A 0 CIRCUIT SCHEMATIC DIAGRAM...