Operating Instructions

2K2100 with STW

Initial installation

The pulley should be balanced to quality 6.3 as

per VDI Directive 2060 and DIN ISO 1940 Part 1

+ Part 2 in order to ensure low-vibration

operation. Note the axial and radial runout of the

centering device on the belt pulley and belt

grooves in relation to the centering device.

CAUTION

Note the maximum specified tensioning force

when tensioning the belts in order to prevent

bearing overload.

The average belt force must be between the

bearings. When assembling, it must be possible

to easily slide the pulley onto the output flange.

Heat the pulley if necessary.

21

3.6.2

Option: version with coaxial output,

only on request

In the case of the version with coaxial output

(shaft stub), also note the balancing type for the

output (see section 3.2).

3.7

Electrical connection, gearchange

The gearbox is electrically connected using the

supplied 8-pole Harting connector (HAN 8 U).

The plug-in connection is located on the shift unit.

3.7.1

Shift unit

Technical data:

Power consumption

85 W

Supply voltage

24 V DC

±

10%

Current consumption 5 A

(max. pull-in current)

The required cable lead diameter is 1.5 mm².

The 24 VDC supply voltage and 5 A current

consumption must be assured at the shift unit plug

on the gearbox.

Losses due to cable length and transition resistors

must be taken into account.

If switching to the shift unit by relay, we

recommend using a varistor, e.g. Siemens type

S14-30 (30 V) to connect to the 24 V voltage pin

2 and pin 3.

Scope of supply:

Sleeve housing, screw connection, socket insert

and 8 jacks, type Harting AWG16, (ZF order no.

4161 298 004).

The shift unit can only be obtained as a complete

part.

Gearbox shift mechanism:

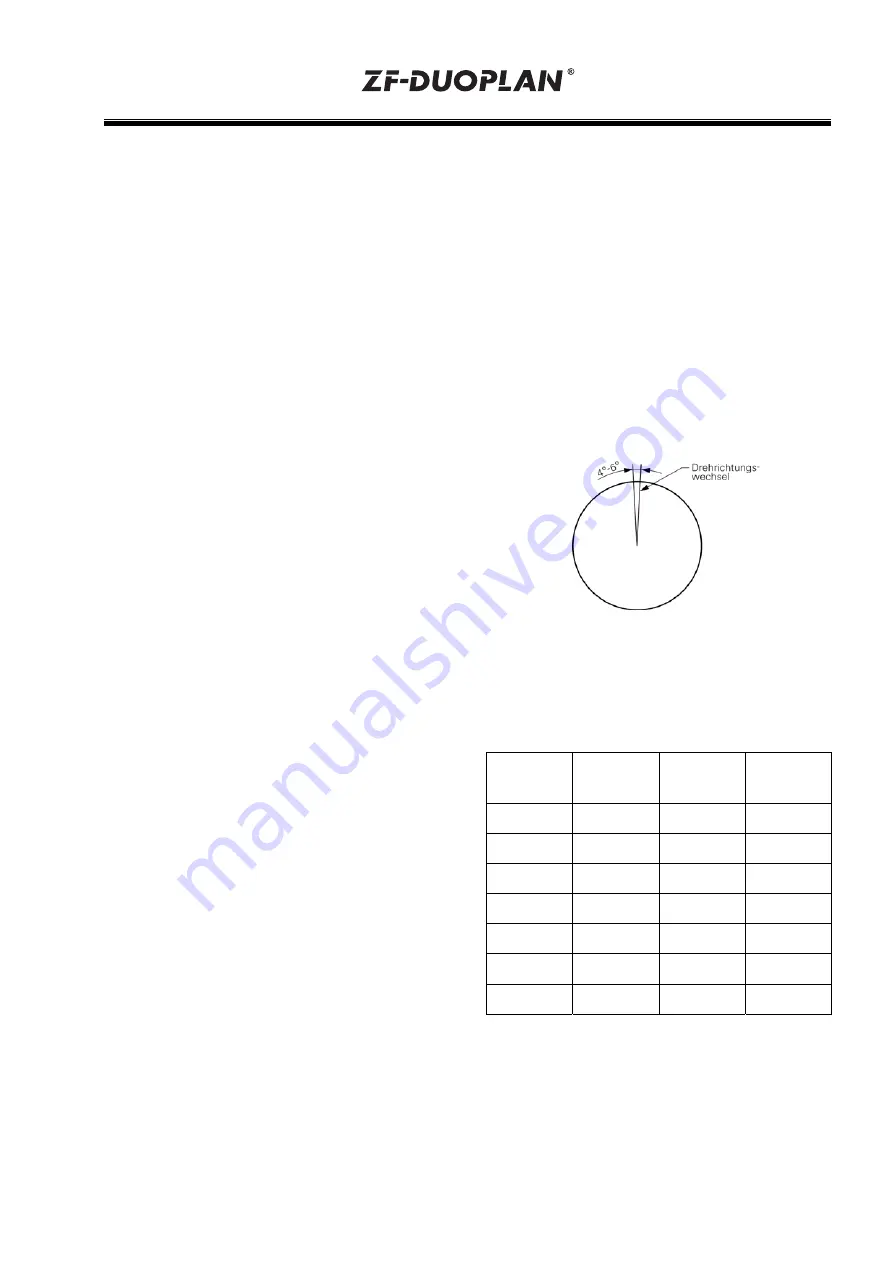

During transmission stage changeover, the main

spindle motor performs a pendulum motion with a

4° - 6° angle with 1 to 5 changes in rotary

direction per second. Major pendulum motion

may lead to damage at the meshing gears.

In average, this means: n

Mot

= 5°/s = 5° 60/min =

300°/min = 300/360 rpm = 0.83 rpm.

Conversion

Pendulum speed

↔

pendulum rotary motion

Speed

[rpm]

Angle

[°/min]

Time

[sec]

Angle

[°/sec]

0.25 90 3.33 5

0.50 180 1.67 5

1.00 360 0.83 5

2.00 720 0.42 5

3.00 1080 0.28 5

4.00 1440 0.21 5

5.00 1800 0.17 5

The machine optimum is to be determined on the

basis of shift tests in relation to the different

masses and thereto connected drag torques of the

spindle.