Operating

Instructions

Initial installation

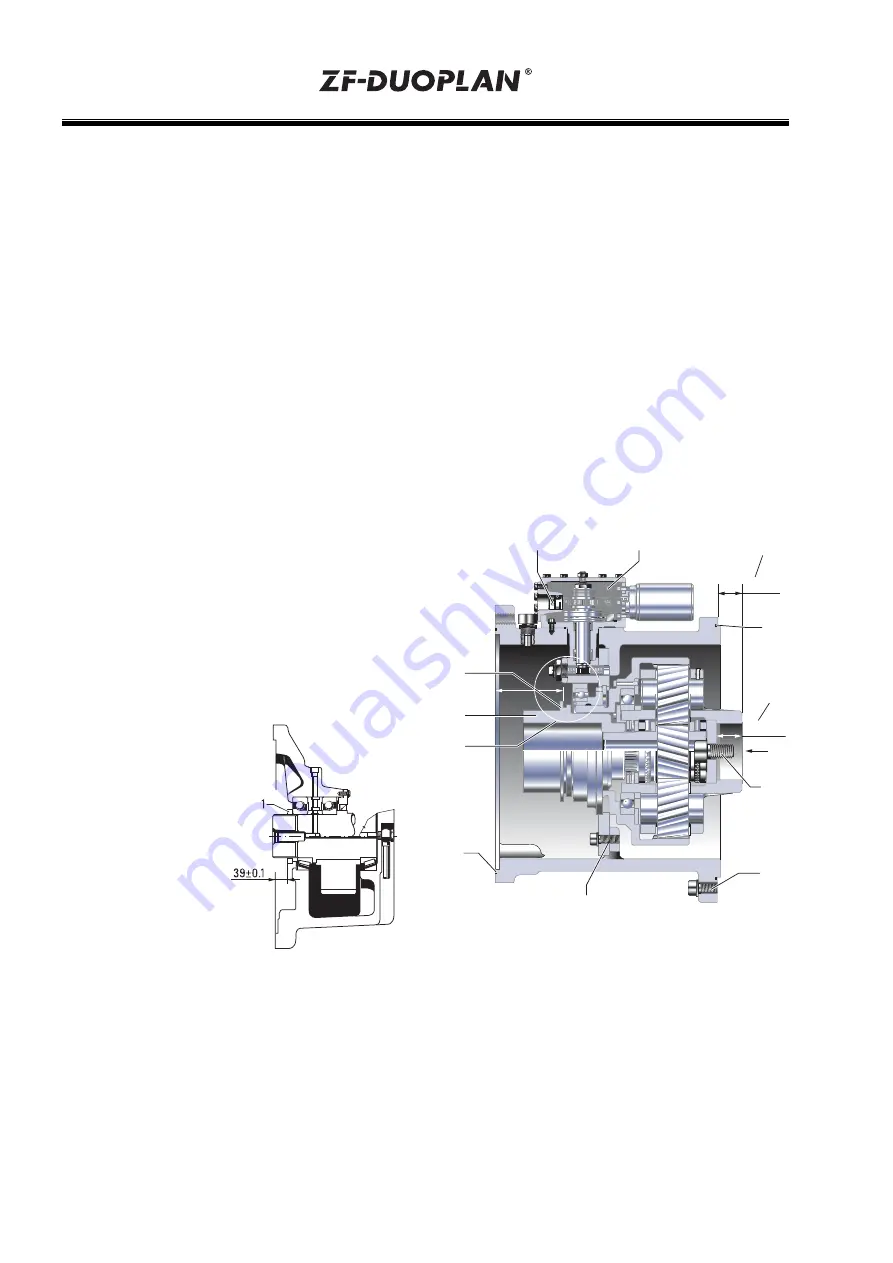

2K2100 with STW

3.3

Mounting of 2K2100 without STW (spur

gear stage) on motor/gearbox

If the 2K2100 without output (without spur gear

stage) is supplied, mount the gearbox as follows.

Clean the flange faces on the gearbox housing and

the machine, check for unevenness and, if

necessary, skim with an oil stone.

First check the following dimensions (see

diagram):

A: 39 ± 0.1 mm is required on the input shaft in

order to allow bracing of the planetary gear carrier

with the machine bearings or spacer ring (1).

B: 41 – 0.5 mm; length of the profile in the

planetary gear carrier

Installation:

14

Slide the planetary gear carrier (profile

N90x2x30x44x9H) with ring gear onto the shaft

with the profile W90x2x30x44x9k. Bolt the

planetary gear carrier using the pan head screw

"D" with hexagon socket head (M24x2x60, with

bore).

Tightening torque: 420 Nm.

023648

Insert the O-ring "C" into the groove, using

standard grease to affix it if necessary. First

position the gearbox housing with the pan head

screws (13xM16x*) "F" and then tighten the

screws diagonally/alternately in several stages

until the final torque (195 Nm) is reached.

Undo the brake disc bolts. The shift mechanism

must be in 1st gear (4:1). Centering the brake disc

relative to the sliding sleeve can influence the

gear change.

NOTE:

The shift mechanism must be in 1st gear (position

S; 4:1). As a result, the sliding sleeve is also

guided. The gearing should be greased to make

installation easier.

A

39.000

41.000

C

B

I

D

F

H

R

P

M

S

T

G

N1

023649

* (not part of ZF scope of supply)